The Use of Microwave Blanch Technology as an Alternative Preparation Method for Freezing Collard Greens

(Brassica olteracea) at Home

J. ROBERTS, L. T. Walker and J.C. Anderson

Dept. of Food & Animal Sciences, Alabama A&M Univ. P.O Box 1628, Normal, AL 35762-1628

This material is based upon work supported by the Cooperative State Research, Education, and Extension Service, U.S. Department of Agriculture, under Agreement No. 00-51110-9762.

Presented at the Institute of Food Technologists International Food Safety and Quality Conference and Expo,

Orlando, FL, November 6, 2003.

Abstract

Most home food preservers do not realize that microwave blanching is an option when preparing fresh vegetables for

frozen storage. Previous research indicated that microwave blanching may be the best method for maintaining nutrients

and physical attributes when preserving vegetables for home freezing. Thus far, only lower wattage microwave blanch

research has been conducted on selected vegetables. Further studies are necessary to determine the effect of the

higher wattage microwave effects of vegetables.

The objective of the study was to determine if microwave blanching,

using varying wattages, is a suitable alternative method for preparing collard greens (Brassica oleracea) for home

freezing.

Freshly harvested collard greens (CG) were blanched for 3 min in covered containers using: boiling water

(BW), steam (ST) and three different wattage microwaves including 1000 watt (MW1), 1200 watt (MW2), and 1300 watt

(MW3). Samples were ice-cooled, placed in freezer bags, and stored at -18oC for 6 months. Enzyme activity

(peroxidase and lipoxydase) and physical parameters (moisture, texture and color) were measured prior to blanching,

immediately following blanch treatments and after 4 and 6 months of frozen storage. Retention of ascorbic acid (AA),

calcium (Ca), iron (Fe) and potassium (K) and sensory characteristics were assessed after 6 months of frozen storage.

Peroxidase activity (POD) was reduced from 0.3-0.35 units in fresh, unblanched samples to 0.001-0.028 units in blanched

CG. Lipoxydase activity (LOX) was reduced from 6160-6700 units in fresh, unblanched CG to 2410-4370 units in

blanched samples. These enzymes when active catalyze the oxidative deterioration of vegetables. All blanching

methods increased greenness of samples. Moisture content for the blanched samples averaged 78% for all treatments,

except BW which averaged 61%. No significant moisture difference (p>0.05) was found among the MW1, MW2, MW3 and ST

treatments. Texture (maximum force) was lowest at 757 N for the BW treatment and highest for ST blanched treatment

(1605 N). Lower texture values can be attributed to a greater cooking effect for the BW treatment. There was no

significant texture difference (p>0.05) among the microwave t treatments. The MW1 treatment retained the highest

percentage (93%) of ascorbic acid (32.9 mg/100g). The BW treatment had the largest (47%) ascorbic acid loss

(16.8 mg/100g) due to leaching effects. No significant difference in ascorbic acid retention (p>0.05) among

the microwave treatments was observed. The MW3 treatment retained 92% Ca (4474 mg/kg), 81% Fe (145 mg/kg)

and 96% K (2310 mg/kg) which was significantly better than any other blanching treatment. Sensory evaluation

(multiple comparison ranking) tested preference using frozen commercial collard greens as a control versus the

5 blanch treatments. There were no significant differences among the treatments for preference.

The study indicated that the overall quality of MW blanched collard greens (for all three wattages) was as good as or

superior to BW and ST blanched vegetables. Further, it was also ascertained that MW blanching is a suitable

alternative to ST or BW blanching when preparing vegetables for home freezing.

Introduction

Vegetables require a short heat treatment or blanching to inactivate enzymes and stabilize quality prior

to and during frozen storage. Conventional blanching processes using boiling water or steam as a heating medium

results in leaching of solids and an ultimate loss of nutrients. A more gentle blanching process involving

microwave technology, which has a more efficient heating system, could have positive effects on the quality

of the finished product.

Most home food preservers do not realize that microwave blanching is an option when preparing fresh vegetables

for frozen storage. Previous research indicates that microwave blanching may be the best method for

maintaining nutrients and physical attributes when preserving vegetables for home freezing. Thus far,

only lower wattage microwave research has been conducted on selected vegetables. Further studies are

necessary to determine the effect of the higher wattage microwave effects on blanching of vegetables.

Objective

The objective of this study was to determine if microwave blanching, using varying wattages,

is a suitable alternative method for preparing collard greens for home freezing.

Materials and Methods

Sample Preparation

Fresh collard greens were harvested fresh in late September (approximately 75 days of age).

Four harvests were conducted. The greens were rinsed three times with tap water to remove

dirt and debris, blanched, and analyzed within 4 hr of harvest. Three different blanching

methods were applied to 200g samples for 3 min in covered containers. The methods included

BW (1900 mL), ST (300 mL water), and MW1, MW2, & MW3 (60 mLwater for each MW treatment).

Blanching time and proportion of vegetable/water were based on average times for BW and

ST recommendations. A 3 min MW blanch time was established in a previous study. This was

the time required to inactivate POD activity. The greens were allowed to sit an additional

1 min following treatment, then ice-cooled for 5 min and drained. Samples were removed and

packed in 1 L plastic bags.

Analyses

Peroxidase and lipoxydase activity, moisture content, texture, and color were measured prior to

blanching, immediately following blanch treatments and after 4 and 6 months of frozen storage.

Sensory characteristics and retention of ascorbic acid (AA), Ca, Fe, and K were assessed after

6 months of frozen storage.

Ascorbic acid

AA was determined by HPLC using a UV detector set at 272 nm and oven temperature set at ambient.

The analytical column was a 250 x 4.6 mm x ¼ in Valco Microsorb (MV 100-5) column. The mobile phase

consisted of 9.5% acetonitrile in DI water, 0.4  L/L ammonium hydroxide, 0.95 g/L hexane sulfonic acid

(pH to 2.8 with phosphoric acid) using the method of Russell (1986). Concentration of AA was expressed as mg/100g.

L/L ammonium hydroxide, 0.95 g/L hexane sulfonic acid

(pH to 2.8 with phosphoric acid) using the method of Russell (1986). Concentration of AA was expressed as mg/100g.

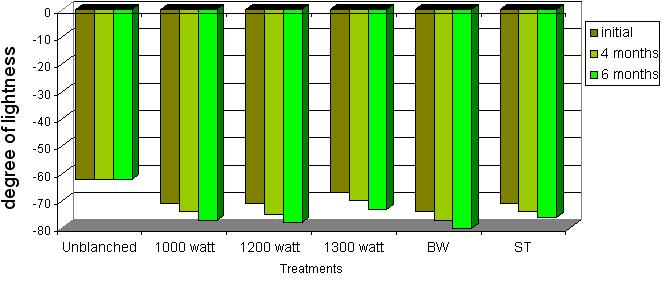

Color

Finely chopped greens were placed into the sample cup (5 cm diameter) of a Hunter

spectrocolorimeter (LabScan Color Flex). L (degree of lightness) values were measured

after standardizing on a white background for the blanched products (Giese 2001).

The color of fresh collard greens was used as a reference.

Lipoxydase activity

LOX activity was determined spectrophotometrically as described by Hamby and Sammuelson (1967) &

revised by Sigma-Aldrich (1997). Absorbance (234 nm) was read at 60 sec intervals for 5 min.

Enzyme activity was expressed as units/mL enzyme.

Peroxidase activity

POD activity was determined spectrophotometrically as described by Chance and Maehly (1955) &

revised by Sigma-Aldrich (1994). Absorbance (420 nm) was read at 20 sec intervals for 5 min.

Enzyme activity was expressed as units/mL enzyme.

Minerals (Ca, Fe, and K)

A microwave-assisted acid digestion procedure for preparing samples (based on US EPA Method 3051

for soil analysis and modified for appropriate foods) was used to prepare the vegetable samples

for analysis. The digestate was analyzed using Inductively Coupled Plasma (ICP) Spectrometry and

concentrations expressed in mg/kg (SW-846, 1994).

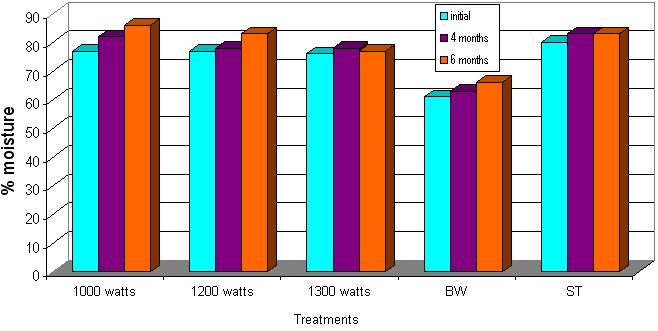

Moisture Content

Moisture content of collard greens was gravimetrically determined by drying at 130°C for 1 hr (AOAC 1990).

Sensory

A 30 or more member consumer sensory panel (Alabama A&M University faculty, staff and students)

used the Multiple-Paired Comparison Test to evaluate the single attribute, preference. Commercial

frozen products were used as controls for this characteristic. Sensory evaluation was conducted

only on cooked products after 6 months of frozen storage (Meullenet and Gross, 1999). The results

were evaluated using a Friedman-type statistical analysis.

Texture

A TMS-TP Texture press (Model FTA-300 Force Transducer) was used for texture evaluation. Chopped,

blanched greens homogeneously filled the test cell (Model CS-2 Thin Blade Shear-Compression) as

described by Ponne, 1994. Texture was determined as force/g of sample.

Statistical Analyses

Collard greens were picked in 4 separate harvests (each harvest was considered a replication).

The vegetables were divided into 6 portions for each treatment. Each portion was divided into 4

parts: 1 for immediate postblanching analyses; 1 for postfreezing analyses at 4 months; 1 for

postfreezing analyses at 6 months and 1 for sensory evaluation. Determination was done in duplicate

for each replicate for chemical and physical parameters. Data was subjected to ANOVA (analysis of

variance) and significantly different means were separated using Tukey's HSD test.

Results and Discussion

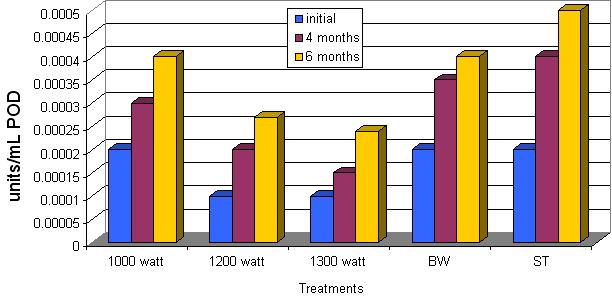

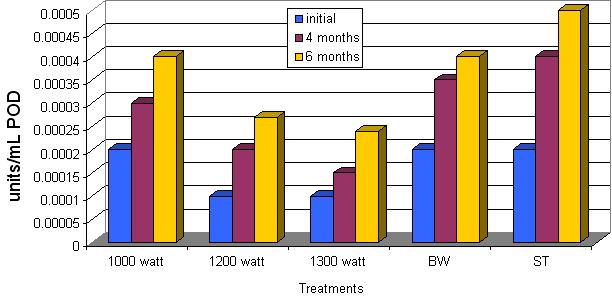

POD enzyme activity in fresh, unblanched collard greens ranged between 0.3-0.35 units and 0.001-0.028

units following blanching (Figure 1) suggesting that MW blanching for all three MW wattages may be

better method for POD inactivation.

Figure 1. POD Activity of Collard Greens

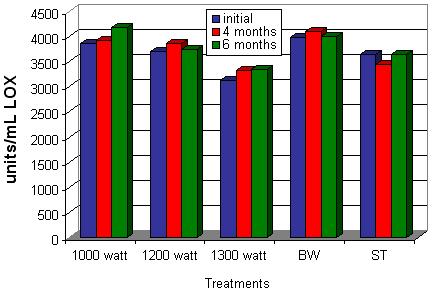

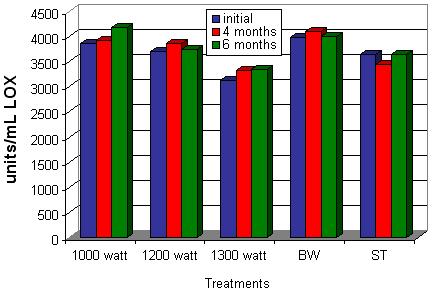

LOX enzyme activity was reduced from 6160-6700 units in fresh, unblanched CG to

2410-4370 units in blanched CG (Fig. 2). These results show that MW blanching, especially MW3,

is the better method for inactivating LOX activity.

Figure 2. LOX Activity of Collard Greens

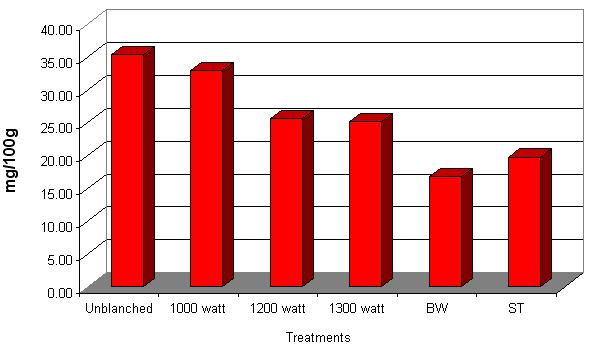

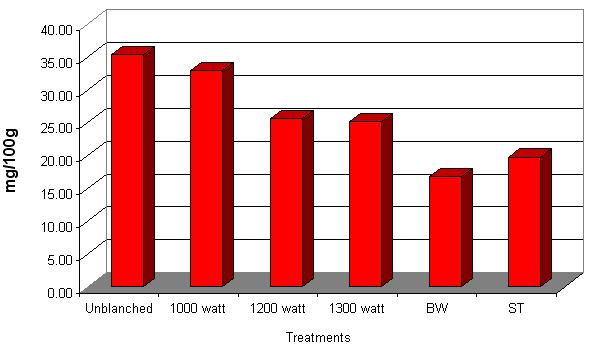

Ascorbic acid retention was highest for MW1 (93%, 32.9 g/100g). The BW treatment had the largest AA loss

(47%, 16.8 mg/100g) due to leaching of nutrients into the large volume of boiling water. No

significant difference in AA retention (p>0.05) among the microwave treatments was observed. See Figure 3.

Figure 3. Ascorbic Acid Retention for Collard Greens

Minerals. MW3 treatment retained 92% Ca (4473 mg/kg), 81% Fe (145 mg/kg) and 96%

K (2310 mg/kg) which was significantly better than any other blanching treatment (Table 1).

Table 1. Mineral Retention for Collard Greens

| Treatment |

Ca (mg/kg) |

Fe (mg/kg) |

K (mg/kg) |

| 1000 watt |

1008 |

125 |

1800 |

| 1200 watt |

1331 |

129 |

1971 |

| 1300 watt |

4473 |

145 |

2310 |

| BW |

1106 |

118 |

761 |

| ST |

2774 |

125 |

1458 |

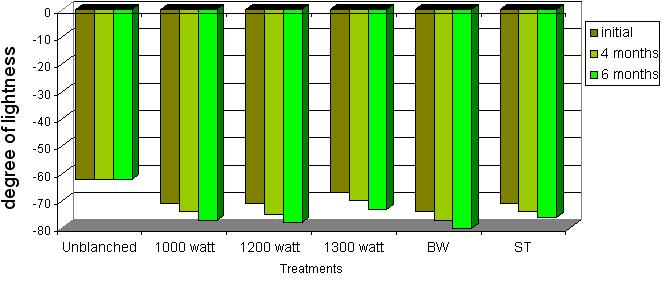

Color-degree of lightness (L) values increased greenness of all samples after blanching (Fig. 4).

Figure 4. Color (L values) for Collard Greens

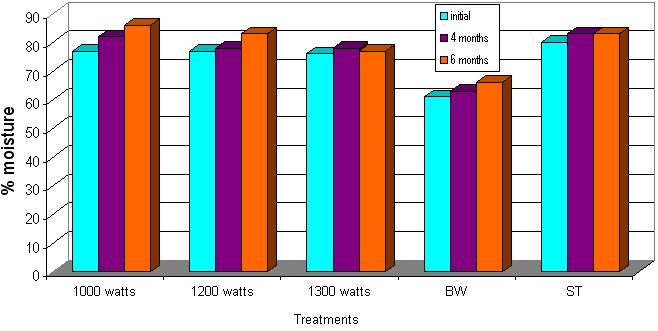

Moisture content for the blanched samples averaged 78% for all treatments, except BW which

averaged 61% (Figure 5). This data suggest that the BW method removed more moisture from the

sample than the other treatments. No significant difference (p>0.05) was found among the MW1,

MW2, MW3, and ST treatments.

Figure 5. Moisture % for Collard Greens

Texture (maximum force) was lowest at 757 N for BW treatment and highest for ST blanched

treatment (1605 N). The lower maximum force value for the BW treatment can be attributed to a

greater cooking effect. There was no significant texture difference (p>0.05) among the microwave

treatments.

Sensory evaluation using multiple comparison ranking tested "preference" using frozen

commercial collard greens as a control versus the other 5 blanch treatments. There were no significant

differences (p>0.05) among the treatments for preference.

Conclusion

The study indicated that the overall quality of MW blanched collard greens for all

three wattages was as good as or superior to BW or ST blanched vegetables.

Further, it was also ascertained that MW blanching is a suitable alternative to

ST or BW blanching when preparing vegetables for home freezing.

Selected References

-

AOAC. 1990. Official Methods of Analysis of AOAC INTERNATIONAL.

1990. 15th Ed., 3rd Rev., secs 963.27.

-

EPA Method 3051. 1994. From SW-846 Online. http://www.epa.gov/epaoswer/hazwaste/test/3_series.htm.

-

Hamberg, M. and Sammuelson, A.C. 1967. J. Biol Chem. 242:5329.

-

Meilgaard, M., Civille, G.V., and Carr, B.T. 1999. Sensory Evaluation Techniques,3rd Ed., CRC Press, Inc., Boca Raton, FL

-

Ponne, C.T., Baysal, T., and Yuksel, D. 1994. J. Food Sci. 59 (5), 1037-1041, 1059.

-

Russell, L.F. 1986. J. Food Science, 51(6):1567-68.

This material is based upon work supported by the Cooperative State Research, Education, and Extension Service, U.S. Department of Agriculture, under Agreement No. 00-51110-9762.

Document Use:

Permission is granted to reproduce these materials in whole or in part for educational purposes only (not for profit beyond the cost of reproduction) provided the authors and Alabama A&M University receive acknowledgment and this notice is included:

Reprinted with permission of Alabama A&M University. J. Roberts,

L. T. Walker and J.C. Anderson. 2003. The Use of Microwave Blanch Technology as an Alternative Preparation Method for Freezing Collard Greens

(Brassica olteracea) at Home. Normal,

AL: Alabama A&M University, Food and Animal Sciences Department.

References to commercials products, services, and information is made with the understanding that no discrimination is intended and no endorsement by the University of Georgia, U.S. Department of Agriculture and supporting organizations is implied. This information is provided for the educational information and convenience of the reader.

The University of Georgia and Ft. Valley State University, the U.S. Department of Agriculture and counties of the state cooperating. The Cooperative Extension Service, the University of Georgia College of Agricultural and Environmental Sciences offers educational programs, assistance and materials to all people without regard to race, color, national origin, age, sex or disability. An Equal Opportunity Employer/Affirmative Action Organization Committed to a Diverse Work Force.

| Contacts: | |

| National Center for Home Food Preservation |

Lloyd T. Walker, Ph.D., Chair |

| 208 Hoke Smith Annex |

Food and Animal Sciences Dept. |

| The University of Georgia |

Alabama A&M University |

| Athens, GA 30602-4356 |

PO Box 1628 |

| |

Normal, AL 35762-1628 |

| |

|

| Tel: (706) 542-3773 |

Tel: (256) 372-4166 |

| Fax: (706) 542-1979 |

Fax: (256) 372-5432 |

| |

Email: lloyd.walker@email.aamu.edu |

| Web: http://www.homefoodpreservation.com |

|

L/L ammonium hydroxide, 0.95 g/L hexane sulfonic acid

(pH to 2.8 with phosphoric acid) using the method of Russell (1986). Concentration of AA was expressed as mg/100g.

L/L ammonium hydroxide, 0.95 g/L hexane sulfonic acid

(pH to 2.8 with phosphoric acid) using the method of Russell (1986). Concentration of AA was expressed as mg/100g.