Influence of Product-entrapped Air and Venting on Lethal Effect in Model Domestic Pressure Canner Studies²

P. Wambura¹, J.C Anderson and L.T. Walker¹

¹Dept. of Food & Animal Sciences, Alabama A&M Univ. P.O Box 1628, Normal, AL 35762-1628

²This material is based upon work supported by the Cooperative State Research, Education, and Extension Service, U.S. Department of Agriculture, under Agreement No. 00-51110-9762.

Paper 17H-19. Presented at the Institute of Food Technologists Annual Meeting, Las Vegas, NV, July 14, 2004.

Abstract

Effects of entrapped air during thermal processing on lethal effect were evaluated in three domestic canners

with seven (7) quart mason jars. Entrapped air volumes in ceramic-bead products were established with various

fillings of water into dry product matrix. Alternate periods of venting included none, 5, 10, and 15 min.

Lethal effects were determined using thermocouples positioned near the bottom, middle, and top of model

product and others outside the jars. Process pressure was monitored throughout each of the 72 runs.

Two canners (All American and Mirro models) were continuously vented during processes while the third

(National Presto) was not - but was vented de facto until lid lock moved up under influence of escaping

gases. Nevertheless, venting times and lack of continuous venting demonstrated little impact.

The higher lethal effects were noted when least product-entrapped air was modeled. Differences were

noted between pressure processes monitored by dial gauge versus calibrated weighted-devices with more

variation of the dial gauge system and greater lethal effect due to manual control basis. Besides

lethal effect differences with product-entrapped air, the three positions of thermocouples registered

least thermal effect at top portions of the jars. All manufacturers of domestic canning kettles

emphasize periods of venting to eliminate air in the canners prior to the timed processing but this

study only reflected suppressed lethal effects when containers manifested product-entrapped air.

Introduction

Consumption of under-processed food constitutes a significant risk of food-borne illness.

It is estimated that food-borne diseases cause approximately 76 million illnesses, 325,000

hospitalizations, and 5,000 deaths in the United States each year (Mead et al., 1999).

Air is a poor heat transfer fluid since it has low specific heat and thermal conductivity.

Recommendations have been published seeking to ensure adequate venting of air from the

pressure canner in manners similar to commercial practices where particularly for flexible

pouches in stacks the call is to remove air from container external contact surfaces

(Ramaswamy and Grabowski, 1996).

Several studies that have been carried out on evaluating the effect of air entrapped in flexible

packages (retortable pouches) reported that air leads to decrease in the heating rate, reduction

in heat transfer rate, and reduction in the accumulated lethality (Weintraub et al., 1989;

Campbell and Ramaswamy, 1992; Ramaswamy and Grabowski, 1996; Brennan et al., 1976).

The main objectives of this study were to contrast canner types and to evaluate temperature

distributions within model product with variation of three levels of product-entrapped air

(three water-fill levels) within the three pressure canners during cooking cycles preceded

by three venting schedules.

Materials and Methods

-

Temperature distribution profiles on the central axes of one-quart mason jars (946 ml)

filled with ceramic beads and three (3) water level fills were conducted with three domestic

pressure canners (an All American model 921, a Mirro model 0522, and a National Presto model 01780).

-

Temperature distribution during venting was measured by copper-constantan thermocouples placed in

specific location in each.

-

Seven (7) Ecklund Harrison thermocouples were placed into the seven (7) mason jars to monitor

temperature profile development inside the jars.

-

The twelve (12) bare thermocouples and 5 more Ecklund-Harrison models were placed in specific

locations around the inside of the cooker to monitor temperature development inside the pressure cooker.

-

Three levels of product-entrapped air were conducted with each of the All American, Mirro and National

Presto pressure canners.

- Jars (946ml) were filled with a 910g of dried ceramic beads.

-

Jars were filled in turn with water to one of the three levels (120, 240 and 360g) at room temperature

and closed with lids and rings before being loaded into the cookers. Rings were not severely tightened

so as to allow air to escape.

-

Experiments were conducted in random orders with venting times of 5, 10, and 15 min. Another series of

experiments were done with no venting throughout.

- Thermocouple output were recorded through the Omega TempScan 1000 data logger.

-

Reference lethal effects were determined by monitoring pressure development with a transducer and

calculating lethal effect with conversion of pressure units to temperature by the Clausius-Clapeyron equation.

-

Thermocouple and pressure transducer outputs were recorded through the Omega TempScan 1000 data logger.

Displaying and recording of the data logger temperatures and pressures were facilitated with a personal

computer and the Omega TempWin software.

-

The beginning of venting time was noted when a constant stream of gases were indicated flowing rapidly

out of the vent tube and continued until the vent tube was capped off.

-

Start of processing was taken as the time when the cooker was brought up to pressure indicated when

the calibrated-weight gauges would jiggle at approximately 70 kPa or when the Presto dial gauge

reached the approximate 70 kPa mark (indicated as 10 psi). 31-minute processes were followed by

slow cooling with the heat turned off.

-

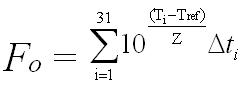

Lethalities (F

-values) were calculated using the General

Method (T

-values) were calculated using the General

Method (T = 121.1°C). Kinetic parameter for C. botulinum spore inactivation (Z = 10C°) was selected. Relative

lethal effects were noted as percentage of the pressure-based lethal effects.

= 121.1°C). Kinetic parameter for C. botulinum spore inactivation (Z = 10C°) was selected. Relative

lethal effects were noted as percentage of the pressure-based lethal effects.

Statistics

Three-by-three design space factors (venting times and water fill levels) were regressed with the RSREG

procedure employing co-variables of unary types for the three canners and the thermocouple positions

using the SAS® for Windows software (Copyright (c) 1999-2001 by SAS Institute Inc., Cary, NC).

Results and Discussion

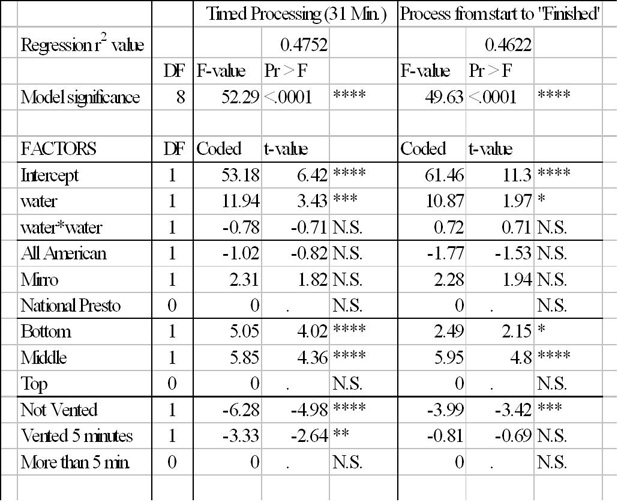

Table 1: Lethal Effects in Minutes based upon Direct Thermocouple Temperature Data

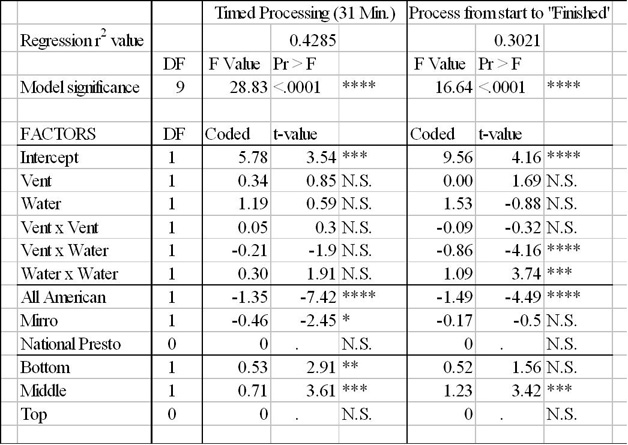

Table 2: Percentages of Lethal Effect of Points inside the Jars based upon Temperature Data Relative to Pressure Data

Notes: **** indicates significance p<0.0001; *** indicates significance p<0.005; ** indicates

significance p>0.01; * indicates significance p<0.05; N.S. indicates not significant

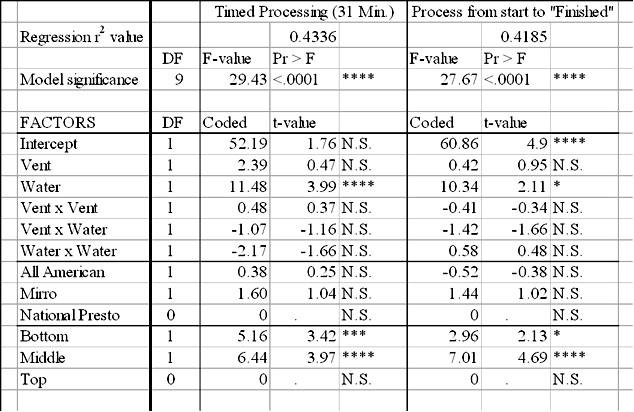

Table 3: Percentages of Lethal Effect of Points outside of Containers based upon Temperature Data Relative to Pressure Data

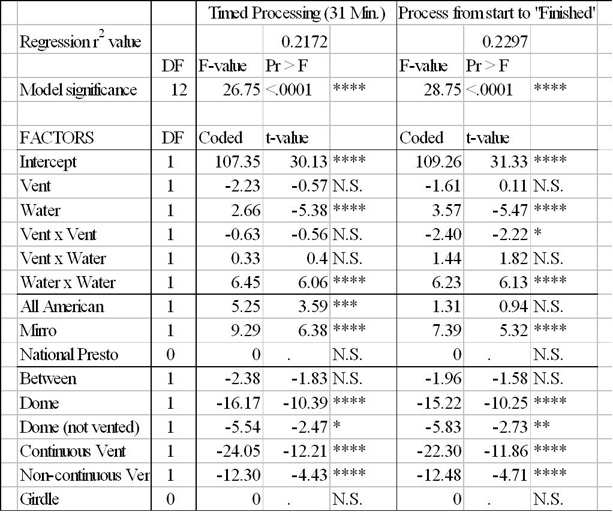

Table 4: Percentages of Lethal Effect of Points inside Containers based upon Temperature Data Relative to Pressure Data Contrasting Categories of Venting Time

Notes: **** indicates significance p<0.0001; *** indicates significance p<0.005; ** indicates

significance p<0.01; * indicates significance p<0.05; N.S. indicates not significant

Pressure Cookers Used

Transducer

Left to right: All American, National Presto, Mirro

Experimental Setup

Discussion

-

Direct thermocouple data transformations to lethal effect analyzed by the RSREG procedure displayed

no design factor significances apart from the unary data of canner model and positions in the jars (Table 1).

-

However, results from this data displayed non-significant differentiation based on the three pressure

canners (as desired) only when the data values were made relative to pressure data (Table 2).

-

When the data were considered relative to pressure, a linear dependence upon water level suggested

improved lethal effects whenever the air-entrapped challenge for process was reduced. --

Prediction by this regression is an ~ 23% [2 X ~ 11.5 coded term] increase of lethal effect

from the most air-entrapped model product to the least air-entrapped model product.

-

Positions in the jars were basis for differing lethal effects with the top position experiencing the

least while the bottom indicated as 5% (3% for total process) and the middle position indicated as

6% (7% for total process) greater than the top position (Table 2).

-

When only the points monitored outside the jars were considered, no significant departure of lethal

effect compared to the "Girdle" sites strapped to the jars was evident for the points suspended in

spaces "Between" the jars (Table 3).

-

The points in the lid dome area whether by the vent or away were much less exhibiting of lethal effect (Table 3).

-

Differences were noted for the continuously vented systems of ~ 22 – 24% less at the vent area and

~ 15 – 16% less in the space away from the vent and appeared to represent a reduced transfer of

heat in areas away from boiling water within which the jars were heated (Table 3).

-

Greater depression of thermal effect for points by the vent may reflect a presence of air

(that reduced the water vapor pressure and its associated temperature equivalent).

-

Evidences by the coded water term of the greater mass of water enabling greater heat capacity to

retain temperature in the vicinity of the jars by the "Girdle" positions were seen in the

regression (Table 3).

-

By three categorical terms of "not vented", "vented 5 minutes", and "vented more than 5 min."

the indication came through that not vented at all was significantly less in lethal effect

than 5 or more minutes (~4% less for the full process) (Table 4).

-

For the shorter (31 min.) timed portion of the process by categorical groups the longer vent

times were also ~3% more effective than the 5 min. vent time (Table 4).

Conclusion

-

Manufacturers of domestic canning kettles emphasize periods of venting (7 to 10 min.)

to eliminate air in the canners prior to the timed processing.

- Five minutes venting was a good as 10 min. in this study.

- Published recommendations appeared to give adequate margins of safety.

-

Nevertheless, this synthetic product model did not represent the full range of potential foods that

could be considered to qualify the recommendation.

Selected References

-

Brennan, J.G., Butlers, J.R., Cowell, N.D., and Lilly, A.E.V. 1976. Food Engineering

Operations, Second edition, Applied Science Publisher Limited, London.

-

Campbell, S. and Ramaswamy, H.S. 1992. Heating Rate, Lethality and Cold Spot Location in

Air-Entrapped Retort Pouches During Over-Pressure Processing. Journal of Food Science, 57: 485-489.

-

Mead, P.S., Slutsker, L., Dietz, V., McCaig, L.F., Bresee, J.S., Shapiro, C., Griffin, P.M and

Tauxe, R.V. 1999. Food-Related Illness and Death in the United States. Journal of Emerging Infectious

Diseases, 5 (10): 607-625

-

Ramaswamy, H.S. and Grabowski, S. 1996. Influence of Entrapped Air on the Heating Behavior of a

Model Food Packaged in Semi-Rigid Plastic Containers during Thermal Processing. Journal of Food

Technology. 29: 88-93. Academic Press Limited.

This material is based upon work supported by the Cooperative State Research, Education, and Extension Service, U.S. Department of Agriculture, under Agreement No. 00-51110-9762.

Document Use:

Permission is granted to reproduce these materials in whole or in part for educational purposes only (not for profit beyond the cost of reproduction) provided the authors and Alabama A&M University receive acknowledgment and this notice is included:

Reprinted with permission of Alabama A&M University. P. Wambura,

J.C Anderson and L.T. Walker. 2004. Influence of Product-entrapped

Air and Venting on Lethal Effect in Model Domestic Pressure Canner

Studies. Normal, AL: Alabama A&M University, Food and Animal Sciences Department.

References to commercials products, services, and information is made with the understanding that no discrimination is intended and no endorsement by the University of Georgia, U.S. Department of Agriculture and supporting organizations is implied. This information is provided for the educational information and convenience of the reader.

The University of Georgia and Ft. Valley State University, the U.S. Department of Agriculture and counties of the state cooperating. The Cooperative Extension Service, the University of Georgia College of Agricultural and Environmental Sciences offers educational programs, assistance and materials to all people without regard to race, color, national origin, age, sex or disability. An Equal Opportunity Employer/Affirmative Action Organization Committed to a Diverse Work Force.

| Contacts: | |

| National Center for Home Food Preservation |

Lloyd T. Walker, Ph.D., Chair |

| 208 Hoke Smith Annex |

Food and Animal Sciences Dept. |

| The University of Georgia |

Alabama A&M University |

| Athens, GA 30602-4356 |

PO Box 1628 |

| |

Normal, AL 35762-1628 |

| |

|

| Tel: (706) 542-3773 |

Tel: (256) 372-4166 |

| Fax: (706) 542-1979 |

Fax: (256) 372-5432 |

| |

Email: lloyd.walker@email.aamu.edu |

| Web: http://www.homefoodpreservation.com |

|

-values) were calculated using the General

Method (T

-values) were calculated using the General

Method (T = 121.1°C). Kinetic parameter for C. botulinum spore inactivation (Z = 10C°) was selected. Relative

lethal effects were noted as percentage of the pressure-based lethal effects.

= 121.1°C). Kinetic parameter for C. botulinum spore inactivation (Z = 10C°) was selected. Relative

lethal effects were noted as percentage of the pressure-based lethal effects.

-values) were calculated using the General

Method (T

-values) were calculated using the General

Method (T = 121.1°C). Kinetic parameter for C. botulinum spore inactivation (Z = 10C°) was selected. Relative

lethal effects were noted as percentage of the pressure-based lethal effects.

= 121.1°C). Kinetic parameter for C. botulinum spore inactivation (Z = 10C°) was selected. Relative

lethal effects were noted as percentage of the pressure-based lethal effects.

Left to right: All American, National Presto, Mirro

Left to right: All American, National Presto, Mirro