Physical and Sensory Characteristics of Reduced Fat Italian Sausage Prepared with Oatmeal

W.L. Kerr*, S.G. Choi and E.L. Andress**

* Dept. of Food Science and Technology, University of Georgia, Athens,GA 30602

** Dept. of Foods and Nutrition, University of Georgia, Athens, GA 30602

Paper 33C-7. Presented at the Institute of Food Technologists Annual Meeting, Las Vegas, NV, July 14, 2004.

Abstract

Reduced fat Italian sausage was prepared with oatmeal at 10, 20, and 30% (w/w), and oatmeal precook times of 0, 2,

and 4 minutes. Cook loss and expressible moisture, cutting force and texture profile analysis, color, and

consumer sensory analysis were analyzed by response surface methodology. Minimum cook loss occurred at 16.3%

oatmeal and 0.76 min precook time, while expressible moisture decreased with increasing oatmeal levels

and decreasing precook time. In general, both cutting force and hardness decreased with oatmeal level.

Measurements of L*, a*, and b* showed a slightly lighter product, and a shift to more red and yellow

cooked product at intermediate oatmeal levels and precook times. For sensory attributes, both oatmeal

level and precook time were significant. Greatest flavor and texture likeability were attained with

oatmeal levels of 3-12%, and precook times of 1.5-3 minutes. Greatest overall likeability occurred over

a region of 0-14% oatmeal, and 1.1-3.3 minutes.

Objectives

| |

1. |

To evaluate the use of oatmeal in the preparation of low fat sausage |

| |

2. |

To demonstrate how different levels and precooking times affected the properties and likeability of the sausage |

Materials and Methods

- SAUSAGE PREPARATION

-

Visible fat removed pork loin was ground and mixed with oatmeal and additional seasoning. After mixing,

the batter was stuffed into a collagen casing.

- Oatmeal levels were 0, 10, 20, and 30%

- Pre-cooking times were 0, 2, and 4 minutes

- Cooking loss and Expressible Moisture

- % Cooking loss = [(Mb – Ma)/Mb×100%] (Mb & Ma : Weight before and after cooking sample)

- % Expressible Moisture = [(Wb – Wa)/wb×100%] (Wb & Wa : Weight before and after compressing sample)

- Texture Analysis

- Cutting force was measured with the Warner-Bratzler shear blade of the TA-XT2i, cut at 4.0mm/s

-

Texture profile (TPA): 1.5cm thick and 1.6cm diameter samples were compressed twice at 2.0mm/s to

50% of their original height.- Hardness, compression, adhesiveness (g.s) were determined.

- Color

- For each batch, L, a, and b were determined using a Minolta chromameter before and after cooking

- Sensory Evaluation

- Flavor, texture, color, and overall acceptability of the sausages were evaluated

- Statistical Analysis

- Treatment differences were analyzed using analysis of variance (ANOVA)

Results

Table 1: Salsa pH vs. ANOVA and response surface statistics for sausage properties as a function of oatmeal level and precook time

| Response |

Range |

Oatmeal

p value |

Precook Time

p value |

Oatmeal* Precook

p value |

Lack of Fit

p > F |

R² |

Optimal Points (oatmeal/precook time) (oatmeal/precook time) |

| %Cooking Loss |

1.2 - 1 3.3 |

0.031 |

0.005 |

0.0038 |

<0.0001 |

0.89 |

2.07% (16.3/0.7) min |

| %Expr Moisture |

2.0 - 7.7 |

<0.0001 |

<0.0001 |

0.075 |

0.0044 |

0.93 |

NA |

| Cutting Force (g) |

790 - 1999 |

<0.0001 |

0.39 |

0.013 |

0.030 |

0.86 |

NA |

| Hardness (g) |

1109 - 4968 |

<0.0001 |

0.073 |

<0.0001 |

0.17 |

0.96 |

NA |

| Adhesiveness (g s) |

|

0.024 |

0.22 |

0.55 |

0.32 |

0.41 |

889 gs (12.9/1.4) max |

| Cohesiveness |

|

<0.0001 |

0.004 |

0.25 |

0.012 |

0.83 |

0.39 (31.7/2.4) sp |

| L* |

42.5 - 50.2 |

0.047 |

0.20 |

0.36 |

0.15 |

0.52 |

45.7 (14.7/2.4) sp |

| a* |

3.86 - 5.28 |

0.67 |

0.19 |

0.14 |

0.0098 |

0.68 |

4.86 (14.7/2.43) max |

| b* |

8.6 - 15.8 |

0.021 |

0.41 |

0.27 |

0.089 |

0.62 |

12.5 (8.93/2.22) sp |

| Sensory Flavor |

4.74 - 6.78 |

<0.0001 |

0.0076 |

<0.0001 |

|

~1 |

7.03 (3.26/3.17) max |

| Sensory Texture |

4.37 - 7.02 |

<0.0001 |

0.12 |

0.0077 |

|

~1 |

6.89 (6.04/2.26) max |

| Sensory Color |

5.3 - 6.02 |

0.86 |

0.0009 |

0.0013 |

|

~1 |

NA |

| Overall Likeability |

4.51 - 6.79 |

<0.0001 |

0.0044 |

<0.0001 |

|

~1 |

6.96 (8.05/2.27) max |

NA=optimum out of data range, min=minimum, max=maximum, sp=saddle point NA=optimum out of data range, min=minimum, max=maximum, sp=saddle point

|

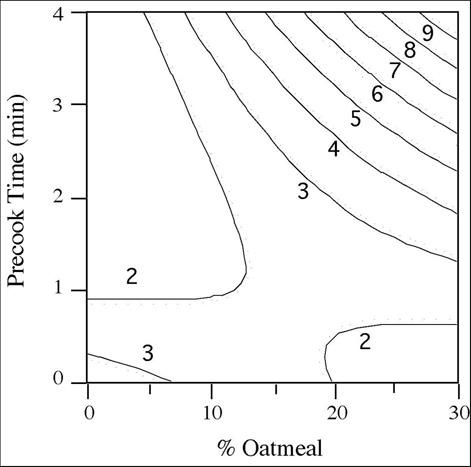

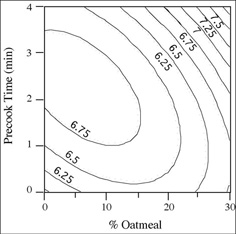

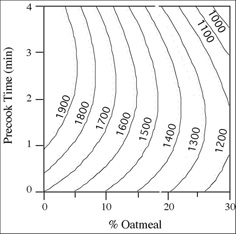

Cooking loss and Expressible water

Figure 1. Cooking loss

- Minimum cook loss(2.1%) was were 16.3% and 0.76min precook time

- Higher levels of oatmeal and increased precook time produced more cook loss

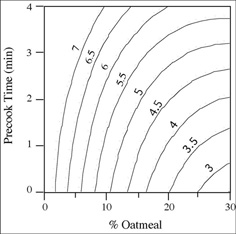

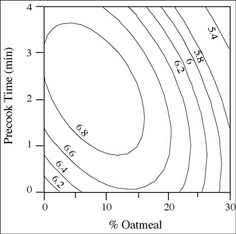

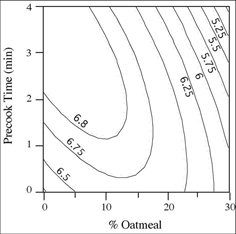

Figure 2. Expressible moisture

- Range was 2 to 7%

- The response surface showed gradually decreasing values at higher level of oatmeal & shorter precook time

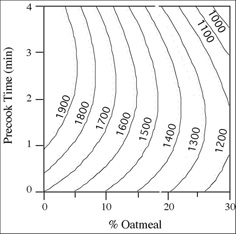

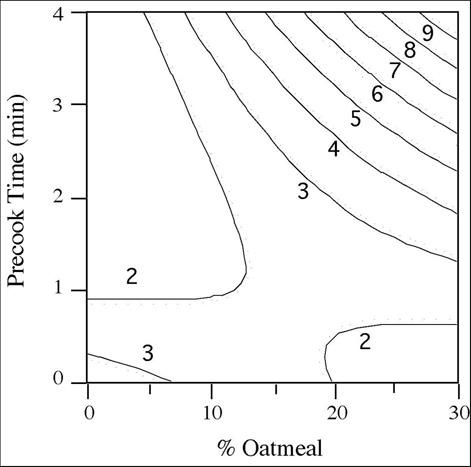

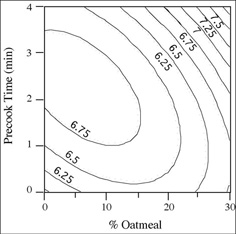

Texture Analysis

Figure 3. Cutting force

- Cutting force decreased with oatmeal level

- Oatmeal level was the greatest contribution to decreasing force

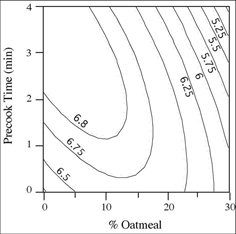

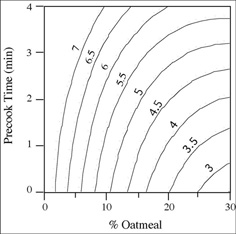

Sensory Evaluation

Figure 4. Flavor

- A maximum value (7.03) was predicted at 3.3% oatmeal level & 3.2 min precook

Figure 5. Texture

- Maximum texture likeability (6.8) was predicted at 6.04% oatmeal and 2.3min precook time

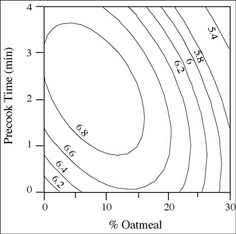

Figure 6. Overall likeability

- Maximum likeability was predicted at 8.05% oatmeal % 2.27 precook time

Conclusion

- A likeable pork sausage can be made in which fat is replaced with up to 15% oatmeal.

- Such products contain improved flavor and texture as compared to low-fat controls.

- Higher levels of oatmeal resulted in a product with more cook loss, softer texture, less cohesion, and minor changes in color.

- Precooking time of the oatmeal is important, particularly to cook loss, cohesiveness, and flavor.

This material is based upon work supported by the Cooperative State Research, Education, and Extension Service, U.S. Department of Agriculture, under Agreement No. 00-51110-9762.

Document Use:

Permission is granted to reproduce these materials in whole or in part for educational purposes only (not for profit beyond the cost of reproduction) provided the authors and the University of Georgia receive acknowledgment and this notice is included:

Reprinted with permission of the University of Georgia. W.L. Kerr, S.G. Choi and E.L. Andress. 2004.

Physical and Sensory Characteristics of Reduced Fat Italian Sausage Prepared with Oatmeal.

Athens, GA: The University of Georgia, Cooperative Extension Service.

References to commercials products, services, and information is made with the understanding that no discrimination is intended and no endorsement by the University of Georgia, U.S. Department of Agriculture and supporting organizations is implied. This information is provided for the educational information and convenience of the reader.

The University of Georgia and Ft. Valley State University, the U.S. Department of Agriculture and counties of the state cooperating. The Cooperative Extension Service, the University of Georgia College of Agricultural and Environmental Sciences offers educational programs, assistance and materials to all people without regard to race, color, national origin, age, sex or disability. An Equal Opportunity Employer/Affirmative Action Organization Committed to a Diverse Work Force.

Contact: