Assessment of Microwave Blanching as a Preparatory Tool for Home Freezing of Yellow Squash

(Cucurbita pepo)

J. ROBERTS, L. T. Walker and J.C. Anderson

Dept. of Food & Animal Sciences, Alabama A&M Univ. P.O Box 1628, Normal, AL 35762-1628

This material is based upon work supported by the Cooperative State Research, Education, and Extension Service, U.S. Department of Agriculture, under Agreement No. 00-51110-9762.

Paper 67C-32. Presented at the Institute of Food Technologists Annual Meeting, Las Vegas, NV, July 14, 2004.

Abstract

Microwave blanching of fruits and vegetables has been identified as a process that retains nutrients

better than conventional blanching methods (boiling water and steam). Only low energy level

(500-700 Watt) microwaves using selected vegetables have been investigated in the past. Further studies

are necessary to determine the effect of today’s higher energy level microwaves on the blanching of

vegetables.

Yellow squash was blanched in covered containers for 3 min using: boiling water (BW),

steam (ST), and 3 microwaves (1000 watt - MW1, 1200 watt - MW2, and 1300 watt - MW3). Samples were

ice-cooled, placed in freezer bags, and stored at –18°C for 6 months. Enzyme activity, physico/chemical,

nutritional and sensory parameters were assessed during and following 6 months of frozen storage.

Peroxidase (POD) activity decreased from 2.77-4.03 units (unblanched - UB) to 0.005-0.138 units

after initial blanching. The MW3 treatment retained 96% Fe (170 mg/kg) and 93% K (2133 mg/kg),

which was significantly higher than the other microwave blanch treatments. Total ascorbic acid (TAA)

retention was highest (14.4 mg/100g) for the ST blanched treatment (97%). There were no significant

TAA retention differences among the MW3 and ST treatments. Texture values were least firm for the BW

treatment (66 Newtons) due to an increased cooking effect. Sensory preference scores indicated a

level of acceptance that was no different from the commercial (control) product.

The study indicated that the overall quality of MW (all 3 energy levels) blanched yellow squash was as good as or superior

to BW and ST blanching methods. The availability of this and other such information to home

preservers of fruits and vegetables could lead to a higher quality of products for consumption.

Introduction

Microwave ovens are now being employed for meal preparation and food preservation instead of

conventional stove top and conventional oven approaches.

Most vegetables require a short heat treatment called blanching. It is the primary means of

inactivating oxidative enzymes present in vegetables and fruits in order to preserve quality prior

to and during freezing and for reducing the surface microbial load. Blanching also aids in

removing tissue gases, shrinking the product, peeling, cleaning and stabilizing color.

Conventional blanching processes utilize rapidly boiling water or steam as a heating medium and

result in leaching of solids which reduces nutritional quality (Brewer, 2002).

Twenty-first century microwave blanching has proven to be 1) the most

economically efficient, 2) better at retaining the nutrient content of treated fruits

and vegetables, and 3) a better time saving method for the home preparation of

vegetables for freezing (Barlow, 1998). Since over 93% of United States

households own a microwave (IMPI, 2003), it is imperative that microwave

blanching as a form of food preparation for home freezing be researched and

usage guidelines communicated to the public.

Objective

The goal of this study was to compare the effects of microwave blanching of

yellow squash utilizing three levels of microwave energy (MW1, MW2 and

MW3) with those of conventional blanching (BW and ST). The objective of this

study was to assess enzyme activity, chemical, physical, nutritional and

sensory parameters following 6 months of frozen storage of microwave blanched

yellow squash.

Materials and Methods

Sample Preparation

Yellow squash was harvested fresh in mid July. The vegetables were rinsed with

tap water three times (to remove dirt and debris), blanched, and assayed for

peroxidase activity within 4 hr of harvest. Yellow squash (200 g samples) was

blanched for 3 min by three methods in covered containers using the required

amounts of water: BW (1900 mL), ST (300 mL), and MW1, MW2, & MW3 (60

mL). Blanching time and proportion of vegetable/water were based on average

times for BW and ST recommendations. MW blanch time was established in a

previous study. This was the microwave blanch time required to inactivate POD

activity. The vegetables were then ice-cooled for 5 min and drained. Samples

were removed and packed in 1-L plastic freezer bags until further analyses.

Analyses

Peroxidase activity, minerals (calcium, iron, potassium and sodium), total

ascorbic acid and texture of unblanched and blanched yellow squash were

determined. Sensory evaluation was determined after 6 months on frozen and

cooked yellow squash.

Peroxidase (POD) Activity

POD activity was determined spectrophotometrically as described by

Chance and Maehly (1955) & revised by Sigma-Aldrich (1994).

Absorbance (420 nm) was read at 20 sec intervals for 3 min. The

unblanched vegetable was used as the control. Enzyme activity was

expressed as units POD/mL vegetable filtrate.

Minerals (Ca, Fe, K and Na)

A microwave-assisted acid digestion procedure for preparing samples

(based on US EPA Method 3051 for soil analysis and modified for

appropriate foods) was used to prepare the vegetable samples for analyses

(Pingitore, 1996). The digestate was analyzed using Inductively Coupled

Plasma (ICP) Spectrometry and concentrations expressed in mg/kg (SW-

846, 1994).

Total Ascorbic Acid (TAA)

TAA was determined by HPLC using a UV detector set at 272 nm. The

analytical column was a 250 x 4.6 mm x ¼ in Valco Microsorb (MV100-5)

column. The method described by Russell (1986) was utilized for this

experiment. The mobile phase consisted of 9.5% acetonitrile in DD water,

0.4  L/L ammonium hydroxide, 0.95 g/L hexane sulfonic acid (pH to 2.8

with phosphoric acid). Concentration of TAA was expressed as mg/100g.

L/L ammonium hydroxide, 0.95 g/L hexane sulfonic acid (pH to 2.8

with phosphoric acid). Concentration of TAA was expressed as mg/100g.

Texture

A TMS-Texturepress (model FTA-300 Force Transducer) was used for

texture evaluation. Homogeneous samples of chopped, unblanched &

blanched vegetables (15 g) were used to fill the Allo-Kramer ten blade test

cell (Model CS-2 Thin Blade Shear-Compression). A one-bite mode test

was performed on each sample (Ponne, 1994; Bourne, 2002). The

transducer cal number was 780 and the transducer speed was set to 1.

Texture was determined as maximum force and expressed in Newtons (N).

Sensory

A 30 or more member consumer sensory panel (Alabama A&M University

faculty, staff and students) used the Multiple-Paired Comparison Test to

evaluate the single attribute, preference. Commercial frozen yellow squash

was used as the control versus the other 5 blanch treatments for this

characteristic. Sensory evaluation was conducted only on cooked yellow

squash after 6 months of frozen storage (Meilgaard et al., 1999).

Statistical Analyses

Data were analyzed by ANOVA (analysis of variance) and significant

different (p<0.05) means were determined using Tukey's HSD test (SAS,

2001). Values were reported as the mean of the four replicates.

Statistical analysis for sensory evaluation used Friedman's analysis T test

(Meilgaard et al, 1999). Significant differences (p<0.05) were determined

using Tukey’s HSD test.

Results and Discussion

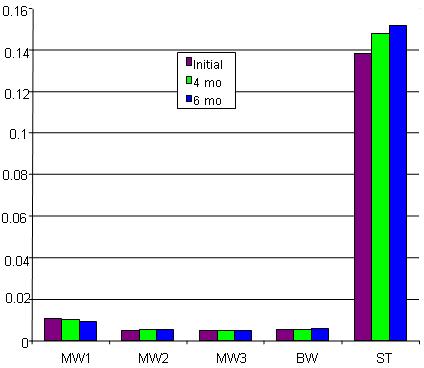

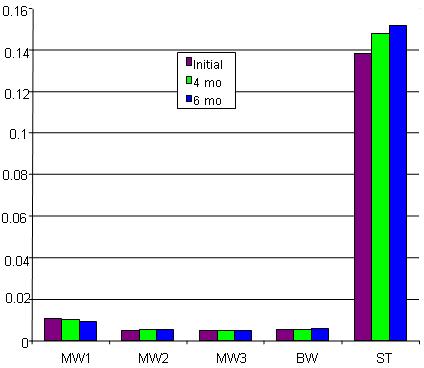

POD enzyme activity in fresh, unblanched yellow squash varied from 2.77-4.03

units to 0.005-0.138 units after initial blanching. POD activity was retarded the

most for MW1, MW2, MW3 and BW treatments at initial blanching and after 4

and 6 months frozen storage. Essentially, no POD regeneration occurred for all

blanching treatments (Figure 1). The ST treatment was significantly higher

(p&0.05) than the other blanching treatments for POD activity.

Enzyme Activity (units POD/mL filtrate)

Treatments

Figure 1. POD Enzyme Activity of Yellow Squash at Initial Blanching and after 4 and 6 Months Frozen Storage

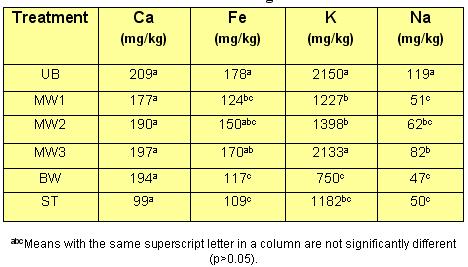

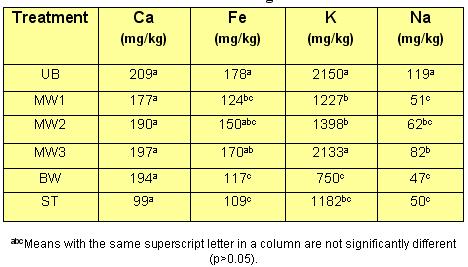

Minerals

MW3 blanch treatment retained 94% Ca (197 mg/kg), 96%

Fe (170 mg/kg), 99% K (2133mg/kg) and 69% Na (82 mg/kg) for

yellow squash. The MW3 blanch treatment was significantly greater for

potassium retention compared to the other microwave blanch treatments.

There were no differences in the blanch treatments for calcium retention,

but the MW3 blanch treatment was significantly greater than the BW and

ST blanch treatments for iron and sodium retention (Table 1).

Table 1. Mineral Retention in Yellow Squash Originally and after 6 Months Frozen Storage

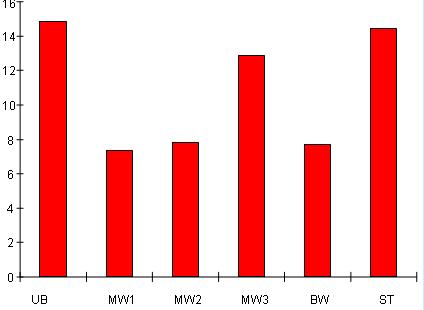

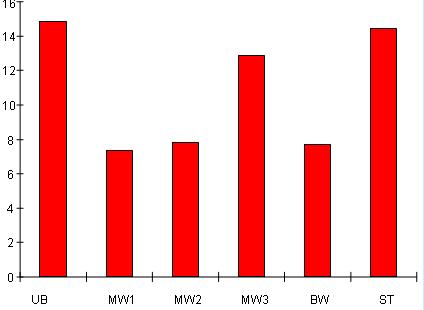

Total Ascorbic Acid retention was highest for the ST blanch treatment (97%,

14.4 mg/100g) followed by the MW3 blanch treatment (87%, 12.9 mg/100g).

MW1 and MW2 blanch treatments were significantly less in TAA retention than

the MW3 blanch treatment but equivalent to the BW blanch treatment

(Figure 2).

TAA (mg/100g)

Treatments

Figure 2. Total Ascorbic Acid Retention in Unblanched and Blanched Yellow Squash after 6 Months Frozen Storage

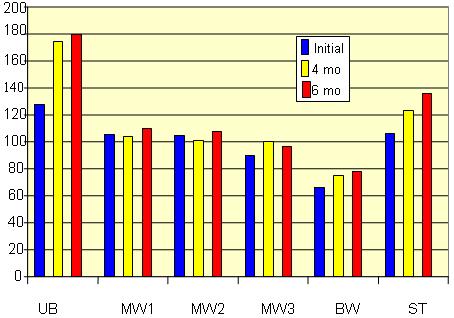

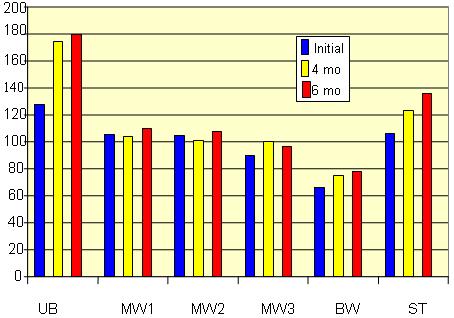

Texture

Unblanched yellow squash shear force was 128 N at initial

measurement. Texture was firmest for the ST blanched treatment (106

N) and least firm for the BW blanched treatment (66 N) after initial

blanching (Figure 3). There were no significant textural differences

(p>0.05) among the three MW and ST treatments at initial blanch and

after 4 months frozen storage.

Shear Force (Newtons/15g)

Treatments

Figure 3. Shear Force Resistance of Unblanched and Blanched Yellow Squash at all Storage Phases

Sensory Evaluation

The results revealed that after 6 months frozen

storage, there were no significant differences in preference among the

treatments (MW1, MW2, MW3, BW, ST and Control).

Conclusion

The three MW blanch and BW blanch treatments decreased

POD activity better than the ST blanch treatment. Mineral

losses may be attributed to interactions with other chemical

compounds and large volumes of water used in the BW blanch

treatment. TAA losses during the blanching process occurred

mostly by leaching of soluble solids or aqueous extraction

rather than by chemical degradation. Also, Ball (1997) stated

that ascorbic acid oxidase and lipoxidase present in squash can

oxidize TAA by generating free radicals from the oxidation of

polyunsaturated fatty acids, which in turn can react with and

damage TAA. This could also explain some TAA loss in

yellow squash. Texture shear force values were least firm for

the BW blanch treatment which was probably due to a

greater cooking effect caused by greater amounts of heat

produced by boiling water. The preference scores for this

experiment indicated that a level of acceptance that was not

different from the commercial (control) vegetable.

The study indicated that the overall quality of MW blanched

yellow squash for all three energy levels was as good as or

superior to BW or ST blanched methods. These microwaves

when used as a preparatory blanching step for freezing of

yellow squash could yield a higher quality product for the home

consumer.

Selected References

-

Bourne, M.C. (ed). 2002. Food texture and viscosity: concept and measurement. 2nd ed. Academic Press, San Diego, CA.

-

Chance, B. & Maehly, A.C. 1955. Methods in Enzymology. 2:773-775.

-

EPA Method 3051. 1994. From SW-846 Online. http://www.epa.gov/epaoswer/hazwaste/test/3series.htm.

-

Meilgaard, M. et al. 1999. Sensory Evaluation Techniques, 3rd Ed., CRC Press, Inc., Boca Raton, FL.

-

Pingitore, N.E. et al. 1996. The Border Basket: Analysis of Toxic Metals in Retail Foods, El Paso-Juarez.

SCERP Project # EHPP961VI-2. The Univ. of Texas at El Paso.

-

Russell, L.F. 1986. J. Food Science, 51(6):1567-68.

-

Sigma-Aldrich, Inc. 1994. Enzymatic assay of Peroxidase (EC 1.11.1.7).

Sigma quality control test procedure for Sigma product P-1432.

This material is based upon work supported by the Cooperative State Research, Education, and Extension Service, U.S. Department of Agriculture, under Agreement No. 00-51110-9762.

Document Use:

Permission is granted to reproduce these materials in whole or in part for educational purposes only (not for profit beyond the cost of reproduction) provided the authors and Alabama A&M University receive acknowledgment and this notice is included:

Reprinted with permission of Alabama A&M University. J. Roberts,

L. T. Walker and J.C. Anderson. 2004. Assessment of Microwave Blanching

as a Preparatory Tool for Home Freezing of Yellow Squash. Normal,

AL: Alabama A&M University, Food and Animal Sciences Department.

References to commercials products, services, and information is made with the understanding that no discrimination is intended and no endorsement by the University of Georgia, U.S. Department of Agriculture and supporting organizations is implied. This information is provided for the educational information and convenience of the reader.

The University of Georgia and Ft. Valley State University, the U.S. Department of Agriculture and counties of the state cooperating. The Cooperative Extension Service, the University of Georgia College of Agricultural and Environmental Sciences offers educational programs, assistance and materials to all people without regard to race, color, national origin, age, sex or disability. An Equal Opportunity Employer/Affirmative Action Organization Committed to a Diverse Work Force.

| Contacts: | |

| National Center for Home Food Preservation |

Lloyd T. Walker, Ph.D., Chair |

| 208 Hoke Smith Annex |

Food and Animal Sciences Dept. |

| The University of Georgia |

Alabama A&M University |

| Athens, GA 30602-4356 |

PO Box 1628 |

| |

Normal, AL 35762-1628 |

| |

|

| Tel: (706) 542-3773 |

Tel: (256) 372-4166 |

| Fax: (706) 542-1979 |

Fax: (256) 372-5432 |

| |

Email: lloyd.walker@email.aamu.edu |

| Web: http://www.homefoodpreservation.com |

|

L/L ammonium hydroxide, 0.95 g/L hexane sulfonic acid (pH to 2.8

with phosphoric acid). Concentration of TAA was expressed as mg/100g.

L/L ammonium hydroxide, 0.95 g/L hexane sulfonic acid (pH to 2.8

with phosphoric acid). Concentration of TAA was expressed as mg/100g.