Storing

Ingredientes Utilizados en las Conservas Preparadas en Casa (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-ingredientes-utilizados-en-las-conservas-preparadas-en-casa

La liofilización (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-la-liofilizacion

Peras (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-peras

Mermeladas, jaleas y compotas (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-mermeladas-jaleas-y-compotas

Carne seca (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-carnes

Carnes (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-carnes

La Congelación de Frutas (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-la-congelacion-de-frutas

Aspectos Básicos de la Preparación de Conservas en Casa (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-aspectos-basicos-de-la-preparacion-de-conservas-en-casa

Rellenos de fruta para tartas, tortas y pasteles (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-rellenos-de-fruta-para-tartas-tortas-y-pasteles

El secado de frutas y vegetales (Deshidratación) (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-el-secado-de-frutas-y-vegetales-deshidratacion

El secado de las plantas medicinales y aromáticas (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-el-secado-de-las-plantas-medicinales-y-aromaticas

Congelación de Vegetales (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-congelacion-de-vegetales

Tomates (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-tomates

Maíz dulce (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-maiz-dulce

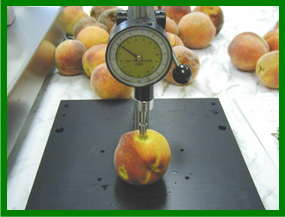

Duraznos, albaricoques y nectarinas (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-duraznos-albaricoques-y-nectarinas

Cerezas (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-cerezas

Manzanas (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-manzanas

Fresas (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-fresas

Proceso Rápido para preparar Pepinillos en Vinagre (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-proceso-rapido-para-preparar-pepinillos-en-vinagre

Papas y Batatas (Camote o Papa Dulce) (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-papas-y-batatas-camote-o-papa-dulce

Judías verdes (habichuelas) (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-judias-verdes-habichuelas

Chiles/Pimientos (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-chiles-pimientos

Raíces comestibles: remolachas, zanahorias, nabos y colinabos (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-raices-comestibles-remolachas-zanahorias-nabos-y-colinabos

Calabazas y Calabacines (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-calabazas-y-calabacines

Canning Salsa Introduction

Check out all of the delicious recipes in the navigation bar to the left.

Want to make your salsa your own? Check out the Choice Salsa recipe!

Arándanos (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-arandanos

Col Fermentada (Chucrut) y Pepinillos (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-fermentacion-col-fermentada-chucrut-y-pepinillos

Sopas (Spanish)

Visite el siguiente sitio web de Penn State University para obtener más información: https://extension.psu.edu/vamos-a-conservar-alimentos-sopas

Syrups for Use in Freezing Fruits

| Type of Syrup | Percent Syrup* | Cups of Sugar** | Cups of Water | Yield of Syrup in Cups |

|---|---|---|---|---|

| Very Light | 10% | 1/2 | 4 | 4 1/2 cups |

| Light | 20% | 1 | 4 | 4 3/4 cups |

| Medium | 30% | 1 3/4 | 4 | 5 cups |

| Heavy | 40% | 2 3/4 | 4 | 5 1/3 cups |

| Very Heavy | 50% | 4 | 4 | 6 cups |

* Approximate

** In general, up to one-fourth of the sugar may be replaced by corn syrup or mild-flavored honey. A larger proportion of corn syrup may be used if a very bland, light-colored typed is selected.

To make the syrup, dissolve sugar in lukewarm water, mixing until the solution is clear. Chill syrup before using.

Use just enough cold syrup to cover the prepared fruit after it has been placed in the container (about 1/2 to 2/3 cup of syrup per pint). To keep fruit under the syrup, place a small piece of crumpled parchment paper or other water-resistant wrapping material on top, and press fruit down into the syrup before sealing the container.

This document was extracted from "So Easy to Preserve", 6th ed. 2014. Bulletin 989, Cooperative Extension Service, The University of Georgia, Athens. Revised by Elizabeth L. Andress. Ph.D. and Judy A. Harrison, Ph.D., Extension Foods Specialists.

Blanching Times

| Vegetable | Blanching Time* (minutes) |

|---|---|

| Artichoke-Globe (Hearts) |

7 |

| Artichoke-Jerusalem | 3-5 |

| Asparagus Small Stalk Medium Stalk Large Stalk |

2 3 4 |

| Beans-Snap, Green, or Wax | 3 |

| Beans-Lima, Butter, or Pinto Small Medium Large |

2 3 4 |

| Beets | cook |

| Broccoli (flowerets 11/2 inches across) Steamed |

3 5 |

| Brussel Sprouts Small Heads Medium Heads Large Heads |

3 4 5 |

| Cabbage or Chinese Cabbage (shredded) |

1 1/2 |

| Carrots Small Diced, Sliced or Lengthwise Strips |

5 2 |

| Cauliflower (flowerets, 1 inch across) |

3 |

| Celery | 3 |

| Corn Corn-on-the-cob Small Ears Medium Ears Large Ears Whole Kernel or Cream Style (ears blanched before cutting corn from cob) |

7 9 11 4 |

| Eggplant | 4 |

| Greens Collards All Other |

3 2 |

| Kohlrabi Whole Cubes |

3 1 |

| Mushrooms Whole (steamed) Buttons or Quarters (steamed) Slices steamed) |

5 3 1/2 3 |

| Okra Small Pods Large Pods |

3 4 |

| Onions (blanch until center is heated) Rings |

3-7 10-15 seconds |

| Peas-Edible Pod | 1 1/2-3 |

| Peas-Field (blackeye) | 2 |

| Peas-Green | 1 1/2 |

| Peppers-Sweet Halves Strips or Rings |

3 2 |

| Potatoes-Irish (New) | 3-5 |

| Pumpkin | cook |

| Rutabagas | 3 |

| Soybeans-Green | 5 |

| Squash-Chayote | 2 |

| Squash-Summer | 3 |

| Squash-Winter | cook |

| Sweet Potatoes | cook |

| Turnips or Parsnips Cubes |

2 |

*blanching times are for water blanching unless otherwise indicated.

Tomato acidification directions

Acidification: To ensure safe acidity levels in whole, crushed, or juiced tomatoes, add the specified amount of acid as indicated in the table below. You can add the acid directly to the jars before filling them with the product. If desired, add sugar to balance the acidic taste, but do not leave acid out. Note that using vinegar may cause undesirable flavor changes.

| Type of acid | Pints | Quarts |

|---|---|---|

| Bottled lemon juice | 1 Tablespoon | 2 Tablespoons |

| Citric acid | ¼ teaspoon | ½ teaspoon |

| 5% Vinegar | 2 Tablespoons | 4 Tablespoons |

Resources for Food Emergencies

Utah State University Extension: A Guide to Food Storage for Emergencies

FoodSafety.gov: Food Safety in a Disaster or Emergency

NC State Extension: Foods to Keep and Discard After a Power Outage

NC State Extension: Infant Food Safety During a Power Outage

University of Georgia: Preserving Food: What to do if the Freezer Stops

Food Storage Resources

Packaging and Storing Dry Foods

Texas A&M Agrilife Extension: Safe Home Food Storage

University of Wisconsin Extension: Storing Fruits and Vegetables from the Home Garden

The FoodKeeper app is a great pocket resource for information about food storage to maximize freshness: FoodKeeper

Storing Food for Emergencies

Ham

Virginia Cooperative Extension: Dry Curing Virginia-Style Ham

University of Georgia Extension: Country Cured Ham

Pork

404: Page Not Found

Whoops! Looks like you've happened upon a page that has been moved or no longer exists...

We’ve recently redesigned the website and reorganized the content. If you’ve bookmarked pages in the old site, you’ll most likely need to update those bookmarks to reflect the new site structure.

Site Search

Google powers our site search... but the new site launch means that those results will be inaccurate until Google re-indexes the new site structure. This may take 1-3 weeks. In the meantime, we invite you to explore our new site to find what you need.

How-to Content

To get you started, here's a list of the main categories of how-to content on the site:

Password Request Recieved

Thank you for requesting access to our Educators' page!

Your interest in our site is greatly appreciated. We have received your request and are processing it promptly. Please keep an eye on your inbox for an email from us (foodpres@uga.edu) containing the password you will need to access this page. If you don't see it right away, please check your spam or junk folder, just in case. We are excited to have you on board and look forward to welcoming you to our educators community!

Bacon

University of Missouri Extension: Home Curing Bacon for a Mild Flavor

Sausage

University of Georgia Extension: Basics of Sausage Making

Drying Fruits and Vegetables

Resources:

University of Georgia Extension: Preserving Food: Drying Fruits and Vegetables

Colorado State University Extension: Drying Fruits

Colorado State University Extension: Drying Vegetables

Low-Temperature Pasteurization Treatment

The following treatment results in a better product texture but must be carefully managed to avoid possible spoilage. Place jars in a canner filled half way with warm (120º to 140º F) water. Then, add hot water to a level 1 inch above jars. Heat the water enough to maintain 180º to 185º F water temperature for 30 minutes. Check with a candy or jelly thermometer to be certain that the water temperature is at least 180ºF during the entire 30 minutes. Temperatures higher than 185ºF may cause unnecessary softening of pickles. Caution: Use only when recipe indicates.

This document was extracted from the "Complete Guide to Home Canning," Agriculture Information Bulletin No. 539, USDA (Revised 2009).

Selection of Fresh Cucumbers

Quantity: An average of 14 pounds is needed per canner load of 7 quarts; an average of 9 pounds is needed per canner load of 9 pints. A bushel weighs 48 pounds and yields 16 to 24 quarts – an average of 2 pounds per quart.

Quality: Select firm cucumbers of the appropriate size: about 1-1/2 inches for gherkins and 4 inches for dills. Use odd-shaped and more mature cucumbers for relishes and bread-and-butter style pickles.

This document was adapted from the "Complete Guide to Home Canning," Agriculture Information Bulletin No. 539, USDA, revised 2015.

Reviewed February 2018.

General Information on Fermenting

The many varieties of pickled and fermented foods are classified by ingredients and method of preparation.

Regular dill pickles and sauerkraut are fermented and cured for about 3 weeks. Refrigerator dills are fermented for about 1 week. During curing, colors and flavors change and acidity increases. Fresh-pack or quick-process pickles are not fermented; some are brined several hours or overnight, then drained and covered with vinegar and seasonings. Fruit pickles usually are prepared by heating fruit in a seasoned syrup acidified with either lemon juice or vinegar. Relishes are made from chopped fruits and vegetables that are cooked with seasonings and vinegar.

Be sure to remove and discard a 1/16-inch slice from the blossom end of fresh cucumbers. Blossoms may contain an enzyme which causes excessive softening of pickles.

Caution: The level of acidity in a pickled product is as important to its safety as it is to taste and texture.

- Do not alter vinegar, food, or water proportions in a recipe or use a vinegar with unknown acidity.

- Use only recipes with tested proportions of ingredients.

- There must be a minimum, uniform level of acid throughout the mixed product to prevent the growth of botulinum bacteria.

Ingredients

Select fresh, firm fruits or vegetables free of spoilage. Measure or weigh amounts carefully, because the proportion of fresh food to other ingredients will affect flavor and, in many instances, safety.

Use canning or pickling salt. Noncaking material added to other salts may make the brine cloudy. Since flake salt varies in density, it is not recommended for making pickled and fermented foods. White granulated and brown sugars are most often used. Corn syrup and honey, unless called for in reliable recipes, may produce undesirable flavors. White distilled and cider vinegars of 5 percent acidity (50 grain) are recommended. White vinegar is usually preferred when light color is desirable, as is the case with fruits and cauliflower.

Pickles with reduced salt content

Recipes for pickles with reduced sodium content are provided in Guide 6 of the USDA Complete Guide to Home Canning.

In the making of fresh-pack pickles, cucumbers are acidified quickly with vinegar. Use only tested recipes formulated to produce the proper acidity. While these pickles may be prepared safely with reduced or no salt, their quality may be noticeably lower. Both texture and flavor may be slightly, but noticeably, different than expected. You may wish to make small quantities first to determine if you like them.

However, the salt used in making fermented sauerkraut and brined pickles not only provides characteristic flavor but also is vital to safety and texture. In fermented foods, salt favors the growth of desirable bacteria while inhibiting the growth of others. Caution: Do not attempt to make sauerkraut or fermented pickles by cutting back on the salt required.

Firming agents

Alum may be safely used to firm fermented pickles. However, it is unnecessary and is not included in the recipes in this publication. Alum does not improve the firmness of quick-process pickles. The calcium in lime definitely improves pickle firmness. Food-grade lime may be used as a lime-water solution for soaking fresh cucumbers 12 to 24 hours before pickling them. Excess lime absorbed by the cucumbers must be removed to make safe pickles. To remove excess lime, drain the lime-water solution, rinse, and then resoak the cucumbers in fresh water for 1 hour. Repeat the rinsing and soaking steps two more times. To further improve pickle firmness, you may process cucumber pickles for 30 minutes in water at 180°F. This process also prevents spoilage, but the water temperature should not fall below 180°F. Use a candy or jelly thermometer to check the water temperature.

Preventing spoilage

Pickle products are subject to spoilage from microorganisms, particularly yeasts and molds, as well as enzymes that may affect flavor, color, and texture. Processing the pickles in a boiling-water canner will prevent both of these problems. Standard canning jars and self-sealing lids are recommended. Processing times and procedures will vary according to food acidity and the size of food pieces.

This document was adapted from the "Complete Guide to Home Canning," Agriculture Information Bulletin No. 539, USDA, revised 2015.

Reviewed February 2018.

Pickled Eggs

There are no home canning directions for pickled eggs. All of the following pickled egg recipes are for storage in the refrigerator. Pickled eggs should never be at room temperature except for serving time, when they should be limited to no more than 2 hours in the temperature danger zone of 40 to 140 degrees F.

Caution: Home pickled eggs stored at room temperature have caused botulism. For the report from the Centers for Disease Control and Prevention (CDC), see http://www.cdc.gov/mmwr/preview/mmwrhtml/mm4934a2.htm The Editorial Note in this report cautions against room temperature pickling and storage, also. The CDC further cautions that to reduce the risk for botulism when pickling, food items should be washed and cooked adequately, and utensils, containers, and other surfaces in contact with food, including cutting boards and hands, should be cleaned thoroughly with soap and warm water. Containers (e.g., jars and lids) in which pickling will occur should be sterilized (e.g., placed in boiling water for a prescribed period).

PICKLING TIPS

Pickled eggs are peeled, hard-cooked eggs in a solution consisting basically of vinegar, salt, spices, and perhaps other seasonings. Pickling solutions are heated to boiling, simmered for 5 minutes, and poured over the peeled eggs. Egg whites tend to be more tender if a boiling solution is used instead of room temperature solutions.

Eggs used for pickling should have clean, sound shells. Small or medium eggs are usually a good choice for pickling so the seasoning can penetrate into the egg. Fresh eggs are the best to use for pickling to ensure the highest quality possible since the eggs will be stored over a relatively long period of time. However, eggs at least a few days old will peel better after boiling.

Cooking and Peeling Eggs

According to the Georgia Egg Commission, the following method of hard-cooking facilitates peeling of ultra fresh eggs. Make a pinhole in the large end of the egg, place the eggs in a single layer in a saucepan, and cover with cold water to an inch above the layer of eggs. Place a lid on the pan and bring eggs to a boil. Remove the pan of eggs from the burner, leaving the cover in place, and allow to sit for 15-18 minutes, adjusting time up or down 3 minutes for larger or smaller eggs. Immediately remove eggs from the pan of hot water with a slotted spoon to a bowl of ice water for one minute. In the meantime, bring hot water to simmering. After one minute in ice water remove eggs back to the simmering water for ten seconds. The ten second interval is important because this allows the shell to expand without expanding the rest of the egg. Peel immediately by cracking the shells of the egg all over. Roll each egg gently between hands to loosen the shell. Peel, starting at the large end of the egg. The peeling may take place under cold running water to help wash the shell off the egg and to minimize the shell breaking into the white.

Another cooking method when you are less concerned about peeling of ultra-fresh eggs is to make a pinhole in the large end of the egg, place the eggs in a single layer in a saucepan, and cover with cold water to an inch above the layer of eggs. Place a lid on the pan and bring eggs to a boil. Turn down the heat and simmer for 15 minutes. Place the eggs in cold water and when cool, remove shells. Crack the shell of the egg all over. Peel, starting at the large end of the egg. The peeling may take place under cold running water to help wash the shell off the egg.

Containers for the Eggs

The container used for the eggs should be one that can be closed or sealed tightly; glass canning jars work well. The eggs are to be completely covered with the pickling solution during storage. A quart-size canning jar will hold about one dozen medium sized eggs. For sterilizing glass jars, see Sterilization of Empty Jars.

Storing Eggs

After making the eggs, the eggs require some time to season (i.e., pick up the flavors from the pickling brine). Keep them refrigerated at all times. If small eggs are used, 1 to 2 weeks are usually allowed for seasoning to occur. Medium or large eggs may require 2 to 4 weeks to become well seasoned. Use the eggs within 3 to 4 months for best quality.

RECIPES

Each of these recipes uses 12 peeled, hard-cooked eggs. The directions for each recipe are to bring all the ingredients except the eggs to a boil, reduce the heat and simmer for 5 minutes. Pack no more than one dozen peeled, hard-cooked eggs loosely into a warm, pre-sterilized quart jar (or other similar size container which can be closed tightly). There needs to be plenty of pickling solution, and enough to completely cover the eggs. Pour the hot pickling solution over the eggs in the jar, cover, and refrigerate immediately.

RED BEET EGGS

1 cup red beet juice (from canned beets)

1½ cups cider vinegar

1 teaspoon brown sugar

a few canned whole tiny red beets (or several slices of beets can be used)

SWEET AND SOUR EGGS

1½ cups pasteurized apple cider

½ cup cider vinegar

1 package (about 12 oz.) red cinnamon candy

1 tablespoon mixed pickling spice

2 tablespoons salt

1 teaspoon garlic salt

DARK AND SPICY EGGS

1½ cups cider vinegar

½ cup water

1 tablespoon dark brown sugar

2 teaspoons granulated sugar

1 teaspoon mixed pickling spice

¼ teaspoon liquid smoke or hickory smoke salt

2 teaspoons salt

CIDERED EGGS

1½ cups pasteurized sweet apple cider or apple juice

½ cup white vinegar

6 thin slices of onion

1½ teaspoons salt

1 teaspoon whole pickling spice

1 peeled garlic clove

DILLED EGGS

1½ cups white vinegar

1 cup water

¾ teaspoon dill weed

¼ teaspoon white pepper

3 teaspoons salt

¼ teaspoon mustard seed

½ teaspoon onion juice or minced onion

½ teaspoon minced garlic or 1 peeled garlic clove

PINEAPPLE PICKLED EGGS

1 can (12 oz.) unsweetened pineapple juice*

1½ cups white vinegar

2 medium onions, peeled and sliced

¼ cup sugar

1 teaspoon salt

1 teaspoon whole pickling spice

*If sweetened pineapple juice is used, omit sugar

Acknowledgements

Recipes adapted and used with permission from:

Peter Piper Picked A Peck of Pickled Eggs, Georgia Egg Commission (undated).

Original Acknowledgements on the Georgia Egg Commission publication: Dr. James C. Acton, Department of Food Science, Clemson University; Dr. Walter M. Britton, Department of Poultry Science, University of Georgia; The American Egg Board, Park Ridge, Illinois; and

Preserving and Pickling Eggs at Home, Cooperative Extension Service, University of Wisconsin.

Reviewed April 2014

Elizabeth L. Andress, Ph.D.

University of Georgia and National Center for Home Food Preservation.

More Sweet Spread Resources

- New Mexico State University Cooperative Extension Service: Home Canned Sweet Spreads Made with Green Chile

- North Dakota State University Extension: From the Garden or Orchard to the Table: Jams and Jellies from North Dakota Fruits

- Information on fruit butters, syrups, and pureés can be found under Canning Fruits and Fruit Products

Storing General Information

Recipes

Dairy and eggs

Seafood products

Meat and poultry products

Fruits

Vegetables

Recipes

Additional resources

- Home Canned Sweet Spreads Made with Green Chile, New Mexico State University Cooperative Extension Service

- Information on fruit butters, syrups, and pureés can be found under Canning Fruits and Fruit Products

Reduced sugar recipes

Marmalades

Preserves

Conserves

Jellies

Jams

General Information on Pickling

The many varieties of pickled and fermented foods are classified by ingredients and method of preparation.

Regular dill pickles and sauerkraut are fermented and cured for about 3 weeks. Refrigerator dills are fermented for about 1 week. During curing, colors and flavors change and acidity increases. Fresh-pack or quick-process pickles are not fermented; some are brined several hours or overnight, then drained and covered with vinegar and seasonings. Fruit pickles usually are prepared by heating fruit in a seasoned syrup acidified with either lemon juice or vinegar. Relishes are made from chopped fruits and vegetables that are cooked with seasonings and vinegar.

Be sure to remove and discard a 1/16-inch slice from the blossom end of fresh cucumbers. Blossoms may contain an enzyme which causes excessive softening of pickles.

Caution: The level of acidity in a pickled product is as important to its safety as it is to taste and texture.

- Do not alter vinegar, food, or water proportions in a recipe or use a vinegar with unknown acidity.

- Use only recipes with tested proportions of ingredients.

- There must be a minimum, uniform level of acid throughout the mixed product to prevent the growth of botulinum bacteria.

Ingredients

Select fresh, firm fruits or vegetables free of spoilage. Measure or weigh amounts carefully, because the proportion of fresh food to other ingredients will affect flavor and, in many instances, safety.

Use canning or pickling salt. Noncaking material added to other salts may make the brine cloudy. Since flake salt varies in density, it is not recommended for making pickled and fermented foods. White granulated and brown sugars are most often used. Corn syrup and honey, unless called for in reliable recipes, may produce undesirable flavors. White distilled and cider vinegars of 5 percent acidity (50 grain) are recommended. White vinegar is usually preferred when light color is desirable, as is the case with fruits and cauliflower.

Pickles with reduced salt content

Recipes for pickles with reduced sodium content are provided in Guide 6 of the USDA Complete Guide to Home Canning.

In the making of fresh-pack pickles, cucumbers are acidified quickly with vinegar. Use only tested recipes formulated to produce the proper acidity. While these pickles may be prepared safely with reduced or no salt, their quality may be noticeably lower. Both texture and flavor may be slightly, but noticeably, different than expected. You may wish to make small quantities first to determine if you like them.

However, the salt used in making fermented sauerkraut and brined pickles not only provides characteristic flavor but also is vital to safety and texture. In fermented foods, salt favors the growth of desirable bacteria while inhibiting the growth of others. Caution: Do not attempt to make sauerkraut or fermented pickles by cutting back on the salt required.

Firming agents

Alum may be safely used to firm fermented pickles. However, it is unnecessary and is not included in the recipes in this publication. Alum does not improve the firmness of quick-process pickles. The calcium in lime definitely improves pickle firmness. Food-grade lime may be used as a lime-water solution for soaking fresh cucumbers 12 to 24 hours before pickling them. Excess lime absorbed by the cucumbers must be removed to make safe pickles. To remove excess lime, drain the lime-water solution, rinse, and then resoak the cucumbers in fresh water for 1 hour. Repeat the rinsing and soaking steps two more times. To further improve pickle firmness, you may process cucumber pickles for 30 minutes in water at 180°F. This process also prevents spoilage, but the water temperature should not fall below 180°F. Use a candy or jelly thermometer to check the water temperature.

Preventing spoilage

Pickle products are subject to spoilage from microorganisms, particularly yeasts and molds, as well as enzymes that may affect flavor, color, and texture. Processing the pickles in a boiling-water canner will prevent both of these problems. Standard canning jars and self-sealing lids are recommended. Processing times and procedures will vary according to food acidity and the size of food pieces.

This document was adapted from the "Complete Guide to Home Canning," Agriculture Information Bulletin No. 539, USDA, revised 2015.

Reviewed February 2018.

Pickling General Information

Drying General Information

Jams & Jellies General Information

2002 SNE Poster

An Updated Look at Home Canning

Holly H. Garner, Elizabeth L. Andress, Ph.D., Anne L. Sweaney, Ph.D., The University of Georgia, Extension Foods and Nutrition, 208 Hoke Smith Annex, Athens, GA 30602-4356.

Presented at the Society for Nutrition Education Annual Conference, St. Paul, MN, July 29, 2002.

Abstract

Home canning is a traditionally popular means of preserving seasonal produce or specialty foods. The last comprehensive survey of U.S. canning practices, published in 1979 by USDA, studied consumer practices used in 1975. Significant lapses in appropriate techniques were documented and later survey reports by others have not revealed major shifts toward improved practices. As research yields new information about how to safely preserve foods and recommended practices for consumers are subsequently changed, people do not necessarily adopt the revised recommendations. Therefore, trained interviewers at the Survey Research Center, University of Georgia, conducted two surveys to determine practices and information sources currently being used by home canners. Between October 2000 and January 2001, 135 telephone interviews from households randomly selected throughout the U.S. were completed. In October 2001, 179 Georgians answered questions in another random telephone survey. Compared to the 1970’s, current findings indicate changes in the amount and types of foods canned at home, as well as methods used. They also document continued use of high-risk practices, including some that could lead to botulism. Friends or relatives are the primary source of instructions for today’s home canners (43.5% in the national survey, 55.1% in the Georgia survey); this practice could promote continued use of outdated information. More people can low-acid vegetables than tomato products or fruits and many use unsafe methods in doing so. Findings document knowledge and canning methods that should be targeted in educational programs for this population. This project was supported by CSREES-USDA under Agreement No. 00-51110-9762.

Introduction

Home canning is a popular means for preserving seasonal produce or specialty foods that helps maintain food for longer periods of time without losing its nutrient content. Although times have changed, many people still use the same food preservation methods that their grandparents did. This presents a problem because as more is understood about how to safely preserve foods the methods people use should be revised and updated as needed. Past surveys have shown that home canners use outdated and even unsafe procedures (2,3). Food was being preserved by methods that increase the risk for spoilage and the health problems that are associated with the consumption of these foods. Therefore, information is needed about the extent to which today’s consumers are canning foods at home, how they obtain their instructions, and if they are using safe procedures.

Objectives

The objectives for this study were to:

- Compare demographic characteristics of home canners today with those canning in the 1970’s.

- Compare the kinds of foods being canned at home today with those being canned in the 1970’s.

- Examine the sources that contemporary home canners look to for canning instructions and how they compare to what was used in the 1970’s.

- Determine if today’s home canners are using more appropriate processing methods than were used in the 1970’s.

Methods

Two telephone surveys were conducted in 2000-2001 by the National Center for Home Food Preservation (NCHFP) at the University of Georgia (UGA) in conjunction with the Survey Research Center (SRC), UGA. Structuring and supervision in an interviewer’s work is essential in order to gather data in a controlled and standardized fashion (4). Thus, interviewers trained in survey research and telephone-interviewing technology by the SRC were used for the interviewing in both surveys. Appropriate supervision during interviews provided quality control. Probability analyses estimated that the number of interviews conducted were more than sufficient to achieve the target levels of precision and accuracy in drawing conclusions on population responses based on sample estimates (1).

Between October 2000 and January 2001, 135 telephone interviews from households randomly selected throughout the U.S. were completed as part of a national survey. A 42-item survey instrument that included 16 open-ended questions was developed by the NCHFP and refined with the assistance of the SRC. 1244 eligible respondents were contacted; these yielded the 501 complete interviews of people canning and/or freezing food at home, for a cooperation rate of 40.3%. Of the 501 in the study, 135 (27%) canned food at home during 1999.

Then in November 2001, 179 Georgians answered a series of 10 home canning questions in another state telephone survey, the Georgia Poll. The Georgia Poll is conducted routinely in a random sampling of adult residents for the purpose of learning the attitudes and opinions of respondents towards several key sets of questions, as well as information about local and national affairs. The home canning interviews were a subset of 427 completed telephone interviews in the Georgia Poll. The cooperation rate for the overall study was 40.5%.

Data from these two UGA surveys were compared to the results of a 1976 national survey conducted by USDA (2). The methodologies for each of these studies are summarized in Table 1.

Results and Discussion

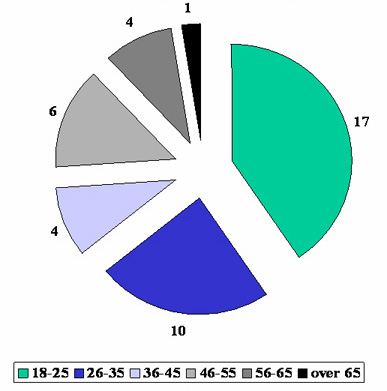

- Approximately 50-58.5% of home canners were 35-64 years of age in each survey. 28-33% were 35-49, while another 20-25.5% were 50-64 years old.

- In the USDA national sample, 39% were 50 years and older and 31% were under age 35. In the NCHFP national sample, there was a higher percentage (41.2) aged 50 years and older and a smaller percentage (24.4) under age 35. The GaPOLL sample had more canners in the younger age categories (under age 65) than the NCHFP sample.

- The numbers of home canners with at least a high school education were higher in the NCHFP (81.5%) and GaPOLL (93.1%) than in the 1975 USDA study (63%). In addition, the number of home canners with formal education beyond high school was also much higher in the more recent surveys (53.3% NCHFP and 67.3% GaPOLL versus 27% USDA).

- The high levels of missing information on income in the NCHFP (40.7%) and GaPOLL (29.1%) surveys make it difficult to describe the true income distribution of those participating in home canning. Of those choosing to report their income, 16.3% and 19.3% (NCHFP and GaPOLL respectively) have household incomes of less than $35,000/year; 43% and 51.6% (NCHFP and GaPOLL respectively) have incomes of more than $35,000.

- In 1975, tomatoes were being canned by 73% of the households surveyed. Today the percentage canning tomatoes has decreased (60% and 34.3% NCHFP and GaPOLL respectively) and vegetables (71.1% and 47.8% NCHFP and GaPOLL respectively) are now the most frequently canned product.

- The increase in the percentage of households canning vegetables focuses concern on the use of improper methods for canning vegetables, which require a pressure processing method.

- The percentage of households canning fruits has decreased slightly from 1975.

- As in 1975, the most often cited source of instructions in the NCHFP and GaPOLL surveys is friends or relatives (43.5% and 55.1% respectively).

- The percentage of home canners using the recommended USDA and Extension Service Publications in 1975 was very small but today that percentage has decreased even more.

- In 1975, 42.6% of home canners were using cookbooks as their source of instruction, but today that number has decreased (16.8% and 15.8% NCHFP and GaPOLL respectively).

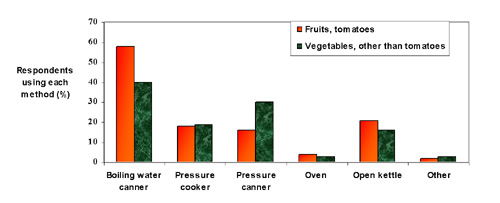

- The usual USDA recommended processing method for canning fruits and tomatoes is boiling water canning, so one would expect a majority of home canners to be using this method. Recommended pressure processes are available as alternatives to the boiling water canner. Oven and open kettle canning have not been recommended by USDA as methods for fruits and tomatoes since 1943. Table 5 contains the methods that home canners report using for the acid-food categories of fruits and tomatoes.

- The percentage of home canners using boiling water canning for fruits and tomatoes has not increased much since 1975. However, the percentage using the open kettle method (no processing of the filled jar) has decreased from 43.6/35.1 (fruits/tomatoes) to 14-22 (NCHFP-GaPOLL).

- More people are using a pressure cooker for processing fruits and tomatoes now than in 1975. A smaller percentage of the NCHFP respondents reported using a pressure canner than in either USDA’s 1975 survey or the GaPOLL.

- The NCHFP and GaPOLL surveys both indicated similar percentages using the boiling water canner for processing fruits and tomatoes. The percentages using all other methods were not consistent in these two surveys.

- The percentage of home canners using boiling water canning for fruits and tomatoes has not increased much since 1975. However, the percentage using the open kettle method (no processing of the filled jar) has decreased from 43.6/35.1 (fruits/tomatoes) to 14-22 (NCHFP-GaPOLL).

- Recommended USDA processing procedures for home canning of vegetables other than tomatoes have only included pressure processes since 1943. Furthermore, boiling water, oven and open kettle canning have been described as unsafe for low-acid foods since that time. Beginning in 1957, USDA Home and Garden Bulletins included a statement to add 20 minutes to processing times used for pressure canners when using a pressure cooker. Therefore, in 1975, USDA did recommend a method for processing vegetables in a pressure cooker (saucepan). However, this endorsement was removed from their recommendations in 1988 with the publishing of the Complete Guide to Home Canning. This latter bulletin stated that recommended small pressure canners hold four quart-size jars; pressure saucepans with smaller volume capacities are not recommended for use in canning. The methods home canners report using for low-acid vegetables are shown in Table 5.

- In 1975, slightly more than half of home canners were using either a pressure canner or cooker for vegetables (56.6 combined), as recommended. A smaller percentage (43.1 combined) reported using either of these methods for vegetable mixtures. Less than half of home canners in the NCHFP (44.2 %) and GaPOLL (32.8 %) surveys reported using either pressure-based method.

- The number of home canners using no processing (the open kettle method) for vegetables was high enough to cause concern in 1975. Unfortunately, today there appears to be little decrease in the percentage of home canners who choose to follow this very risky practice.

- The percentages of home canners today (3.3 and 7.4, NCHFP and GaPOLL respectively) also reporting the use of oven canning methods are of concern.

- In 1975, slightly more than half of home canners were using either a pressure canner or cooker for vegetables (56.6 combined), as recommended. A smaller percentage (43.1 combined) reported using either of these methods for vegetable mixtures. Less than half of home canners in the NCHFP (44.2 %) and GaPOLL (32.8 %) surveys reported using either pressure-based method.

- Prior to 1978, paraffin was recommended in USDA publications for sealing jellies and jams. Then in a 1978 USDA bulletin, a 5-minute boiling water process was recommended for sealed jars of jellies, jams, conserves, marmalades, and preserves for those residing in warm or humid climates; the use of paraffin was restricted as an option for jelly only. USDA has recommended only a boiling water process for all jams and jellies since 1988.

- The GaPOLL results indicate that the number of home canners using a boiling water process for jellies and jams has increased since 1975. However, less than half of home canners today (48.8 percent) are following this practice, while 35% report using open kettle methods, 9% oven canning and 7% pressure canning. In 1975, 85/87% (for jams/jellies) used the open kettle method, while 12.6/9.5 and 3.9/5.1 used boiling water and pressure methods, respectively.

Conclusions

- Current surveys reveal that greater adoption of science-based home canning techniques is needed, a finding similar to the 1975 national USDA survey.

- One finding of greatest concern is the lack of pressure-based processing methods for vegetables. A large percentage of home canners are at high risk for foodborne illness, including botulism.

- Findings document risky practices and knowledge that should be targeted in educational programs and publications.

- Ongoing analyses indicate interactive effects for age and education with choices of processing methods and sources of instruction.

References

- Bason, J. 2001. Materials and methods statement. Survey Research Center, The University of Georgia, Athens, GA.

- Davis, C. A., and L. Page. 1979. Practices used for home canning of fruits and vegetables. USDA Home Economics Research Report No. 43. Washington, DC: Government Printing Office.

- Hatfield, K. 1981. Changing home food production and preservation patterns. National Food Review 27:22-25.

- Lavrakas, P. J. 1987. Telephone Survey Methods: Sampling, Selection and Supervision. Applied Social Research Methods Series, Volume 7. SAGE Publications, CA.

This material is based upon work supported by the Cooperative State Research, Education, and Extension Service, U.S. Department of Agriculture, under Agreement No. 00-51110-9762.

Document Use:

Permission is granted to reproduce these materials in whole or in part for educational purposes only (not for profit beyond the cost of reproduction) provided the authors and the University of Georgia receive acknowledgment and this notice is included:

Reprinted with permission of the University of Georgia. Garner, H.H., E.L. Andress, and A.L. Sweaney. 2002. An updated look at home canning. Athens, GA: The University of Georgia, Cooperative Extension Service.

References to commercials products, services, and information is made with the understanding that no discrimination is intended and no endorsement by the University of Georgia, U.S. Department of Agriculture and supporting organizations is implied. This information is provided for the educational information and convenience of the reader.

The University of Georgia and Ft. Valley State University, the U.S. Department of Agriculture and counties of the state cooperating. The Cooperative Extension Service, the University of Georgia College of Agricultural and Environmental Sciences offers educational programs, assistance and materials to all people without regard to race, color, national origin, age, sex or disability. An Equal Opportunity Employer/Affirmative Action Organization Committed to a Diverse Work Force.

Contact:

National Center for Home Food Preservation

208 Hoke Smith Annex

University of Georgia

Athens, GA 30602-4356

Tel: (706) 542-3773

Fax: (706) 542-1979

Web: http://www.homefoodpreservation.com

2002 Disseminating Information

Disseminating Science-based Home Food Preservation

Information on the Internet

B. A. NUMMER1, E. L. Andress1, J. A. Harrison1, M. A. Harrison2, and W. L. Kerr2. (1) Dept. Foods and Nutrition Extension, University of Georgia, 208 Hoke Smith Annex, Athens, GA 30602, (2) Dept. Food Science and Technology, University of Georgia.

Paper 46B-5. Presented at the Institute of Food Technologists Annual Meeting Anaheim, CA, June 17, 2002.

Abstract

Home food preservation remains an important and popular cultural activity. The safety of these products and processes remains the number one concern. The National Center for Home Food Preservation (NCHFP) was created to help meet the needs of both Extension agents and consumers for science-based information. As part of the NCHFP mission a web site was created to locate, review, and disseminate research-based home food preservation information. The web site, www.homefoodpreservation.com, offers publications from U.S.D.A. guides and bulletins, the University of Georgia, literature reviews of current topics, links to other state Cooperative Extension homepages, seasonal tips, multimedia demonstrations, FAQs, contact lists and a variety of other resources. Initial feedback from a sampling of Cooperative Extension agents has been favorable. Experienced home preservers have also given favorable reviews, while inexperienced home food preservers commented that they are a bit overwhelmed. The initial comments and popularity of the site indicates that it is meeting its objectives of providing resources to Cooperative Extension professionals and increasing public awareness of science-based safe home food preservation techniques.

Introduction

According to the latest Nielsen Media Research survey there are now 92 million Americans over the age of sixteen on the Internet (CommerceNet, 1999). This is almost half of the population. This incredible growth in access has made the Internet an excellent source for educational and reference materials. The Internet is fast becoming an important tool for food safety specialists, allowing for rapid location of specific information. One food safety resource, the National Food Safety Database, had over 10,000 requests per day, over 145,000 distinct users, and an international audience of 85 countries (Tamplin, 1998). The need for access to food safety information will no doubt markedly increase in the coming years, with new food safety regulations, media attention, and advances in Internet technologies.

Material and Methods

Web site. The web site was constructed by the Web Instructional Development group, a part of the University of Georgia Center for Continuing Education, Athens, GA and members of the National Center for Home Food Preservation management team.

Design Analysis. Site design analysis was performed using criteria developed by authors at Yale and Dartmouth Universities (Lynch and Horton, 1997).

Assessment. An assessment of objectives was obtained from a small survey group of 37 educators and consumers and from direct feedback. Web site users were encouraged to send direct feedback and a 15-question survey was created (Exhibit 1) to solicit users feedback.

Results and Discussion

User-centered design. The NCHFP web site users are both consumers and professionals. Consumers range from first-time home food preservers to highly experienced food preservers. Professionals include Cooperative Extension professionals, teachers, researchers, journalists, and publishers. The survey group consisted of 17 Cooperative Extension agents, 17 consumers, and 3 others.

The front page. As an informational site, the front page (Figure 1) establishes an overall visual design with the NCHFP logo. It identifies and gives a brief explanation of the purpose of the site, and provides a site overview by presenting links to its major sections. This page answers the questions, Where am I? What is it like here? What do these people do? What kind of stuff will I find? As a reference site visitors are able to tell at a glance if the information they are seeking is inside. Ninety-two percent felt the home page was “very useful” in its current form.

Figure 1. National Center for Home Food Preservation Front Page

Objectives. Clear and simple goals are key to successful web sites (Table 1).

Authors. It is critical the audience understand who the NCHFP is and the USDA message of using only “science-based” information. The survey group was asked “On your first visit to the web site was it clear whom the NCHFP was?” Eighty-one percent said “yes”, 16% said “yes, but I had to look some” and 3% said “no, I found that information, but it was not completely clear”. A second question asked, “On your first visit to the web site was it clear what “science-based” guidelines and recommendations on Home Food Preservation are?” Sixty-eight percent responded “yes”, 22% responded “yes, but I had to look some”, 5% responded, “no, I found that information, but it was not completely clear, and 5% responded they “did not find that information”.

Navigation. An easy hierarchal structure amenable to both the experienced web surfer and the novice was desired. Eighty-six percent of our survey group responded that the web site was “well categorized and easy to follow”; while 14% responded that it “could be figured out with some effort”.

Pages. Individual pages were created to be simple and consistent. The survey group responded that the placement of buttons and links, colors used, and overall page layouts were “well done and appealing” (76%), “pretty good” (19%), and “nothing special” (3%). The survey group also responded that the graphic appeal of our site was “professionally done and contemporary in appeal” (73%), “pretty good” (24%), and “nothing special” (3%).

Bandwidth. Sixty-five percent of the respondents had a telephone modem or similar slow Internet connection (including all consumer respondents), while 38% reported having a cable modem or similar faster Internet connection. Keeping bandwidth usage to a minimum was critical in serving these users. Some of the Adobe Acrobat™ PDF and Real Media™ files are large for slower connections (Table 2). Some respondents indicated the site was too slow (1 reply) or they had difficulty with large multimedia files (6 replies). Providing alternate sources (e.g. CD-rom, print, downloadable files) for heavy bandwidth files would help alleviate some of these problems.

Interactivity and Search. As both an informational and reference web site we sought to provide quick access to relevant information. When information cannot be located in a menu the search section can guide a user through internal and external search resources to find information. There is also an “Info request” form. Over 85% of the survey group indicated they found the search features “very useful”. Written feedback from novice computer users indicated they had difficulties understanding and using these search functions. Thus, redesigning the “search” topic to make it a logical and simplistic tool more amenable to both novice and expert computer users will be considered.

Multimedia. Some topics benefit by visual enhancement. We created digital video, audio, and animation. This section was the most troublesome of the web site content where 51% of our survey group felt the multimedia section was less than “very useful”. Survey group participants had problems with slow connections, downloading required software, and in getting the multimedia software to run. To address these problems additional means of delivering these files are being considered (e.g. CD-rom). The results may have also been influenced by the minimal content of this section. More content is scheduled to be added.

Change in knowledge and behaviors. Initial comments and popularity of the site indicate that it is meeting its objectives of providing resources to the Cooperative Extension System and increasing public awareness of science-based safe home food preservation techniques. Overall 34 of 37 surveyed felt that the web site would be a positive influence to serve the home food preservation needs of educators. One felt there would be “no influence” due to the lack of usable materials and two consumers had “no opinion”. All 37 respondents felt the web site would be a positive influence on consumers. Seventy-one percent of the survey group felt the “more information on the web site the better”. Two respondents, both were novice food preservers, felt the information “seemed like too much” or was “far too much”. This may suggest the need for “beginner friendly” resources for an introduction to the web site and its contents.

Suggestions. Written suggestions for materials to add included: a site map, why preserve foods for beginners, what your Extension office can do for you, what’s new page for the site, Latin foods, low sugar recipes, links to master gardeners, metric conversions, links for international visitors, a food pH guide, hazardous recipe listing, food safety of preserved gifts, new fruits and vegetable varieties, as well as numerous requests for narrow information topics (e.g. lemon curd, and pomegranate). Additional materials are currently being created and reviewed for placement on the web site. A full-time Webmaster has been hired for site management, further design and building of the site, improvement of access in areas identified by this research, and ongoing evaluation of the site.

References

Lynch, P. and S. Horton, 1997. Web Style Guide. Yale University. Available at: http://info.med.yale.edu/caim/manual/ Accessed 17 May 2002.

Access Board. 2001. Web-based Intranet and Internet Information and Applications. Washington DC. Available at: http://www.access-board.gov/sec508/guide/1194.22.htm. Accessed 1 Jun 2002.

CommerceNet. 1999. Industry Statistics. Available at: http://www.commerce.net/research/stats/wwwpop.html. Accessed 5 Jun 2002.

Tamplin, M.L. 1998. National Food Safety Database. Project No. 98-EFSQ-1-0330. The Food Safety and Quality National Initiative Abstracts. Washington, DC.: U.S. Department of Agriculture. Available at: http://www.reeusda.gov/pas/programs/foodsafety/98abs.htm. Accessed 10 Jun 2002.

Exhibit 1. Survey for Center Web Site

The National Center for Home Food Preservation

1. Describe yourself

45% [17] Cooperative Extension Agent

[ ] State Cooperative Extension Specialist or Program Assistant

3% [ 1] Other University Faculty or Staff

[ ] Extension Volunteer / Master Food Preserver

45% [17] Consumer (Home Food Preserver)

5% [ 2] Other ____________________ e.g. Food Writer, Author, etc.

Total 37

2. Rate your experience level in Home Food Preservation

43% [16] Experienced

24% [ 9] Average Experience

24% [ 9] Some Experience

8% [ 3] Little experience

[ ] No experience

Total 37

3. What type of Internet connection are you using?

14% [ 5] Below 33.6 Kbps telephone modem or I don’t know numbers,

but it is a slow connection.

49% [18] 56Kbps telephone modem.

3% [ 1] Cable modem or I don’t know speeds, but it is a fast

connection.

35% [13] University or other high speed network connection

Total 37

4. On your first visit to the web site was it clear whom the National Center for Home Food Preservation was?

81% [30] Yes

16% [ 6] Yes, but I had to look some

3% [ 1] No, I found that information, but it was not completely clear

[ ] No, I had trouble finding that information

Total 37

5. On your first visit to the web site was it clear what “science-based” guidelines and recommendations on Home Food Preservation are?

68% [25] Yes

22% [ 8] Yes, but I had to look some

5% [ 2] No, I found that information, but it was not completely clear

5% [ 2] No, I had trouble finding that information

Total 37

6. In your opinion, the amount of information on our web site is:

3% [ 1] Far too much

3% [ 1] Seems like too much

23% [ 8] Appropriate

71% [25] The more the better

Total 35 No reply 2

7. In your opinion, the organization of our web site is:

86% [31] Categorized and easy to follow

14% [ 5] Could be figured out with some effort

[ ] Confusing and difficult to follow

Total 36 No reply 1

8. In your opinion, the graphic appeal of our home page is:

73% [27] Professionally done and contemporary in appeal

24% [ 9] Pretty good

3% [ 1] Nothing special

Total 37

9. In your opinion, the placement of buttons and links, colors used, and overall page layouts are:

76% [28] Well-done and appealing

19% [ 7] Pretty good

3% [ 1] Nothing special

Total 37

10. Please visit and rate the section topics of our web site for usefulness (please do not rate the topics on content - more content will be added to sections as we continue our project). Place a check mark in the box of your choice.

| Information is: | Very Useful | Somewhat useful | Not Useful |

|---|---|---|---|

| Home Page | 34 (92%) | 3 (8%) | |

| Publications | 31 (84%) | 6 (16%) | |

| Search Our Site | 30 (88%) | 4 (12%) | |

| Search CES Sites | 30 (86%) | 5 (14%) | |

| Seasonal Tips | 19 (56%) | 11 (33%) | 3 (9%) |

| Info Request | 22 (71%) | 7 (26%) | 2 (6%) |

| Multimedia | 17 (49%) | 13 (37%) | 5 (14%) |

| FAQs | 29 (85%) | 4 (12%) | 1 (3%) |

| Links | 32 (94%) | 2 (6%) | |

| “How do I?” | 36 (100%) |

11. Please write section topic ideas that are not included in our web site that you feel would be useful (e.g. a site map).

Site Map, Why preserve foods for beginners, what your extension office can do for you, what’s new page for the site, latin foods, low sugar pages, links to master gardeners, metric conversions,

12. If you found useful information, was it available in a computer format that was accessible to you? (e.g. MS PowerPoint PPT, Adobe Acrobat PDF, Macromedia Flash, and Real Media).

81% [30] Yes

19% [ 7] Yes, but I had to or would need to download software to

make the information accessible.

[ ] No

Total 37

13. In your opinion, will this web site serve educators in the area of home food preservation?

92% [34] Positive influence

3% [ 1] No influence (responded not enough materials yet for educ.)

[ ] Negative influence

6% [ 2] No opinion

Total 37

14. In your opinion, will this web site serve consumers in the area of home food preservation?

100% [37] Positive influence

[ ] No influence

[ ] Negative influence

Total 37

15. What sources of frustration did you encounter on the web site? Please elaborate. You may also write general comments here.

Site was too slow (2 replies), trouble with Real Media/multimedia (6 replies), overwhelming information overload.

Reviewed by Elaine D’Sa, Ph.D. and Elizabeth Andress, Ph.D., National Center for Home Food Preservation.

This material is based upon work supported by the Cooperative State Research, Education, and Extension Service, U.S. Department of Agriculture, under Agreement No. 00-51110-9762.

Document Use:

Permission is granted to reproduce these materials in whole or in part for educational purposes only (not for profit beyond the cost of reproduction) provided the authors and the University of Georgia receive acknowledgment and this notice is included:

Reprinted with permission of the University of Georgia. Nummer, B.A., E. L. Andress, J. A. Harrison, M. A. Harrison, and W. L. Kerr. 2002. Disseminating science-based home food preservation information on the Internet. Athens, GA: The University of Georgia, Cooperative Extension Service

References to commercials products, services, and information is made with the understanding that no discrimination is intended and no endorsement by the University of Georgia, U.S. Department of Agriculture and supporting organizations is implied. This information is provided for the educational information and convenience of the reader.

The University of Georgia and Ft. Valley State University, the U.S. Department of Agriculture and counties of the state cooperating. The Cooperative Extension Service, the University of Georgia College of Agricultural and Environmental Sciences offers educational programs, assistance and materials to all people without regard to race, color, national origin, age, sex or disability. An Equal Opportunity Employer/Affirmative Action Organization Committed to a Diverse Work Force.

Contact:

National Center for Home Food Preservation

208 Hoke Smith Annex

The University of Georgia

Athens, GA 30602-4356

Tel: (706) 542-3773

Fax: (706) 542-1979

Web: http://www.homefoodpreservation.com

2002 Heat Penetration

Heat Penetration Studies of Stewed Tomatoes in 6, 8, and 17 Quart Household Pressure Retorts

R.J. Pakola and E.L. Andress, Dept. of Foods and Nutrition, The University of Georgia, 208 Hoke Smith Annex, Athens, GA 30602-4356.

Paper 46B-7. Presented at the Institute of Food Technologists Annual Meeting Anaheim, CA, June 17, 2002.

Abstract

Most current home pressure canning recommendations were developed using standard 17 to 21 quart pressure retorts. Today's marketplace offers a variety of smaller pressure-based cookers/canners. Retort size has the potential to affect come up and cooling rates, which contribute to the sterilizing value of a pressure process. As heating and cooling times are reduced so is total lethality. The objective of this study was to compare f(h) values, cumulative lethalities, and potential safe process times during pressure processing of stewed tomatoes in 6, 8, and 17 quart household pressure retorts. Stewed tomatoes were prepared and packed into 8 oz glass home canning jars. Jars were processed at 121.1°C for 25 minutes in 6, 8, and 17 quart pressure retorts after a 10 minute exhaust of the retort. Heat penetration data were collected at the cold spot, previously determined to be the geometric center of the jar. Continuous temperature profiles from 15 replications were collected using copper-constantan needle thermocouples connected to an electronic data logger. Potential process times and cumulative lethal rates were calculated for the destruction of Clostridium botulinum spores. The cumulative lethal rate did not reach the target F0 (3.0) during the process. The majority of the lethality was achieved during cooling. Processing in smaller retorts resulted in lower f(h) values (p<.001). Calculated process times from the data collected so far were found to be equivalent but due to the need to verify some data with additional work, a final conclusion about process schedules cannot be made at this time, Home canning in very small retorts should be avoided until safe process recommendations can be determined.

Introduction

Currently, home canning in smaller pressure retorts is not recommended by USDA and the Cooperative Extension System (USDA, 1994). Existing recommendations were determined using standard size home canning pressure retorts that have a 17 or 21 quart capacity. Smaller pressure retorts are widely available in 4, 6, and 8 quart capacities. "Pressure canner" is a term usually associated with 16 quart and larger capacities. A recent survey by the National Center for Home Food Preservation indicates that people are using smaller pressure retorts to can food at home (Andress, 2001). Past research suggests that 4 quart retorts require a longer process time to achieve an equivalent lethality (Taube and Sater, 1948; Nordsiden and others, 1978). Thus home canning in smaller retorts may not produce a safe product.

Objective

The purpose of this study was to compare heating characteristics and potential process recommendations of a product in standard and smaller size pressure retorts.

Materials and Methods

Stewed tomatoes were selected for this study; the recipe used in this study is described in Figure 1. Half pint jars were filled with 200 + 10 grams stewed tomatoes for all experiments. Each retort load consisted of five jars. Jars were processed at 121.1°C for 25 minutes following a 10 minute exhaust (vent).

Heating profiles were collected in 6, 8, and 17 quart capacity aluminum pressure retorts using Ecklund needle type copper-constantan (type "T") thermocouples.

The cold spot, or slowest heating point in the jar, was determined from data taken at the center and half inch increments below the center by using 4 different lengths of needle probes. Data were recorded using the DAS-TC (Keithley Instruments, 1996) data acquisition system. The rate of heating, expressed as f(h), was determined and compared using the data analysis software (SAS Inc., 1999-2001).

For process calculations, heating profiles were collected at the cold spot in 15 jars of stewed tomatoes per retort size. Data were recorded using the E-Val™ Monitoring System (Ellab Inc., 2000). Data were imported into thermal processing software (TechniCAL Inc., 1998) to determine f(h) values, potential process times (Bb), and cumulative lethalities. A target lethality (F0) of 3.0 minutes was selected based on the choice of Clostridium botulinum as the microorganism of concern.

Figure 1. Stewed Tomatoes Recipe

Ingredients

- 2 quarts halved tomatoes

- ¼ cup chopped celery

- ¼ cup chopped onions

- 2 teaspoons celery salt

- 2 teaspoons sugar

- ¼ teaspoon salt

Procedure

Select firm, ripe Roma tomatoes. Wash and place tomatoes in boiling water until skins split. Dip in cold water and remove the skins and cores. Slice tomatoes into halves. Combine all ingredients in a large saucepan and cover. Heat to a boil and simmer for 10 minutes. Fill five half-pint canning jars, leaving ½ inch headspace. Remove air bubbles, adjust headspace if necessary, and wipe jar rims. Secure two-piece metal lids. Process jars in a pressure canner.

Results and Discussion

COLD SPOT LOCATION

The f(h) value it the slope of the straight line portion of the heating curve. A larger f(h) value indicates a slower rate of heating. The slowest heating point of stewed tomatoes in half pint jars is the geometric center of the jar (Table 1).

| fh | |||

|---|---|---|---|

| Thermocouple placement | n | Mean1 | Standard deviation |

| center | 15 | 32.5A | 2.0 |

| ½" below center | 15 | 31.5B | 2.0 |

| 1" below center | 13 | 29.0B | 3.3 |

| 1½" below center | 11 | 23.9B | 4.7 |

| 1Means in the same column with different letters are significantly different (p<.05) | |||

THERMAL CHARACTERISTICS

Jar temperature did not start to increase until the end of the 10-minute exhaust (Table 2). Mean jar temperatures achieved by the end of the 25-minute process were the same (p<.001) in the 6 and 8 quart retorts (Table 2).

| Retort size (quart) | |||

|---|---|---|---|

| 6 | 8 | 17 | |

| Initial | 79.3 ± 5.81 | 80.5 ± 2.1 | 76.8 ± 3.2 |

| Start of exhaust | 76.8 ± 4.4 | 78.3 ± 2.3 | 74.1 ± 2.3 |

| End of exhaust | 79.8 ± 2.9 | 79.4 ± 2.1 | 76.0 ± 1.9 |

| Start of process | 84.8 ± 2.0A2 | 85.7 ± 1.0 A | 81.4 ± 2.1B |

| End of process | 113.7 ± 0.6A | 113.7 ± 0.6A | 112.2 ± 0.7B |

| At 36 min cooling | 72.9 ± 5.2 | 86.0 ± 3.9 | 79.1 ± 6.0 |

| 1Mean ± standard deviation 2Values in the same row with different letters are significantly different (p<.001) |

|||

EFFECT OF RETORT SIZE

Retort temperatures across experiments were controlled (Table 3).

The f(h) values increased with retort size (Table 3). The jars processed in the smaller retorts had a faster rate of heating (p<.01). The difference between the f(h) values was not significant between the 6 and 8 quart retorts, probably because there is less difference in size between the 6 and 8 quart retorts as compared to the 8 quart and 17 quart retorts.

Target F0 (3.0) was not achieved in any retort by the end of the process time; at least 2/3 of the cumulative lethality was achieved during cooling (Table 3).

Even though the average calculated process time appears to follow the trend of f(h) values, the maximum achieved in each size retort does not. In practice, home canning process times are rounded off to the next highest 5-minute interval. Therefore, if these results were to be used for recommending a process time, based on the worst-case jar in each retort, the recommended process time for all three sizes would be 40 minutes (Table 3).

| Retort size (quart) | |||

|---|---|---|---|

| 6 | 8 | 17 | |

| Retort temperature (°C) | |||

| End of exhaust | 101.4 ± 0.61 | 102.5 ± 0.4 | 102.7 ± 0.1 |

| During process | 121.4 ± 0.1 | 121.2 ± 0.1 | 121.1 ± 0.0 |

| f(h) | 30.6 ± 1.4A2 | 31.3 ± 1.5 A | 33.1 ± 1.3sB |

| Cumulative F (min) | |||

| End of process | 0.9 ± 0.2 | 0.9 ± 0.1 | 0.6 ± 0.1 |

| End of cool in retort | n/a3 | 4.8 ± 0.6 | 3.0 ± 0.5 |

| Calculated process times (min) | |||

| Mean B(b) | 33.6 ± 1.5 | 33.8 ± 0.9 | 36.0 ± 0.6 |

| Maximum B(b) | 37.3 | 35.9 | 37.0 |

| Potential recommendation | 404 | 40 | 40 |

| 1Mean ± standard deviation 2Values in the same row with different letters are significantly different (p<.01) 3Cooling data not available due to equipment failure 4Maximum B(b) rounded up to the next 5 minute increment |

|||

Conclusions

The target F0 was not achieved during the process. Most of the cumulative lethality was acquired during cooling.

Jars processed in smaller retorts (6 and 8 quart) had smaller f(h) values indicating a faster rate of heating during the process time than occurred in the 17 quart retort. This resulted in higher cumulative lethality for the smaller retorts, which was unexpected. These results are not consistent with past research on smaller retorts.

The 6 quart retort did not provide reliable cooling data. Conclusions cannot yet be drawn about the entire process in all three sizes of retorts.

In addition, the 17 quart retort had shorter come-up and cool down times than have been previously documented with older models (Toepfer et al., 1946). The 17 quart retort will hold a much larger volume than the 6 and 8 quart retorts; this study limited the number and size of jars to what was determined to be a full load in the smallest retort. Future work should explore the effect of varying the number and size of jars in the 17 quart retort.

References

- Andress, E. L. 2001. A national survey of current home canning practices in the US. National Center for Home Food Preservation, Department of Foods and Nutrition, The University of Georgia, Athens, GA. Unpublished data.

- Ellab Inc., 2000. E-Val Basic, V. 2.0. Software and Documentation, Ellab Inc., Arvada, CO.

- Keithley Instruments Inc., 1996. DAS-TC Data Acquisition System. Keithley Instruments Inc., Cleveland, OH.

- Nordsiden KL, Thompson DR, Wolf ID, Zottola EA. 1978. Home canning of food: effect of a higher process temperature (250° F) on the safety of low-acid foods. J Food Sci. 43:1734-1737.

- SAS Inc., 1999-2001. Statistical Analysis Software, v. 8.02. for Windows, SAS Institute Inc. Cary, NC.

- Taube, K. and Sater, V.E. 1948. Canning vegetables in the pressure saucepan. J Home Econ. 40:197-198.

- TechniCAL Inc., 1998. Carlsoft, V. 1.3.3. Thermal Processing Software, TechniCAL, Inc., New Orleans, LA.

- Toepfer, E.W., Reynolds, H., Gilpin, G. L., and Taube, K. 1946. Home canning processes for low-acid foods. USDA Technical Bulletin No. 930. Washington, DC: Bureau of Home Economics, U.S. Department of Agriculture.

- USDA. 1994. Complete guide to home canning. Agriculture Information Bulletin No.539. Washington, DC: CSREES-U.S. Department of Agriculture.

This material is based upon work supported by the Cooperative State Research, Education, and Extension Service, U.S. Department of Agriculture, under Agreement No. 00-51110-9762.

Document Use:

Permission is granted to reproduce these materials in whole or in part for educational purposes only (not for profit beyond the cost of reproduction) provided the authors and the University of Georgia receive acknowledgment and this notice is included:

Reprinted with permission of the University of Georgia. Pakola, R.J. and E.L. Andress. 2002. Heat penetration studies of stewed tomatoes in 6, 8, and 17 quart household pressure retorts. Athens, GA: The University of Georgia, Cooperative Extension Service.

References to commercials products, services, and information is made with the understanding that no discrimination is intended and no endorsement by the University of Georgia, U.S. Department of Agriculture and supporting organizations is implied. This information is provided for the educational information and convenience of the reader.

The University of Georgia and Ft. Valley State University, the U.S. Department of Agriculture and counties of the state cooperating. The Cooperative Extension Service, the University of Georgia College of Agricultural and Environmental Sciences offers educational programs, assistance and materials to all people without regard to race, color, national origin, age, sex or disability. An Equal Opportunity Employer/Affirmative Action Organization Committed to a Diverse Work Force.

Contact:

National Center for Home Food Preservation

208 Hoke Smith Annex

The University of Georgia

Athens, GA 30602-4356

Tel: (706) 542-3773

Fax: (706) 542-1979

Web: http://www.homefoodpreservation.com

2002 Jicama

Effect of Fill Weight and Initial Temperature on

Processing Time for a Home Pickled Jicama Relish

H.H. Garner and E.L. Andress, Department of Foods and Nutrition, The University of Georgia, 208 Hoke Smith Annex, Athens, GA 30602-4356.

Paper 46B-6. Presented at the Institute of Food Technologists Annual Meeting Anaheim, CA, June 17, 2002.

Abstract

Pickled vegetables are popular home preserved condiments. The increasing variety of produce in the marketplace offers opportunities for greater diversity in condiments such as salsa and relishes than has traditionally been available in the U.S. Jicama was studied for its potential use in home pickled products with a crisp texture. The objective of this study was to determine the effect of typical consumer procedural variations on heat penetration when processing an acidified jicama relish recipe. Variations were made in fill weight and initial temperature (IT) of the filled jars. An original recipe with an equilibrium pH of 3.5 was developed for heat penetration studies using a hot pack, pint jars and boiling water canner. Product temperatures were continuously recorded at the predetermined cold spot throughout come-up time, 35 minutes in boiling water, and air cooling of jars. Fifteen jars (five jars in each of three canner loads) were used for each procedural variation of fill weight and IT. Processing was done in a 17-quart boiling water canner on a household gas range. Fill weight had a significant impact on both maximum jar temperature obtained and final process time recommendation. Heat applied during come-up had no effect on jar temperature with the overfill. A decrease of 5°C (64.5 vs. 69.7) in IT had no effect on either maximum jar temperature reached at the end of come-up or the 35 minutes at boiling. However, analysis of the maximum jar temperature reached at the end of come-up or the 35 minutes at boiling. However, analysis of the worst case low IT jar would result in a longer process time than for the higher IT product. This study documents the effects of some consumer practices on process lethality for a cubed relish product. Overfills should be avoided to insure expected heating rates and final maximum temperatures. Specifying a minimum number of jars to a home canning recipe could be considered.

Introduction

- Pickled products are low acid foods that have had their pH lowered to 4.6 or below by the addition of acid or vinegar before thermal processing in order to produce a safe product.

- A USDA survey of home canning practices in the 1970's (Davis and Page, 1979) indicated that 20% of home canners make products with combinations of acid and low acid ingredients and use inappropriate methods for processing; a 2000-2001 survey by the University of Georgia had similar findings (Andress, 2001).

- Improperly formulated pickled products may allow for growth of the organism C. botulinum, which leads to toxin formation and the potentially fatal food intoxication, botulism.

- Improperly processed pickled products may allow room for the growth of mold, yeast and/or bacteria that produce spoilage.

Hypotheses

- As fill weight of jars increases, the f(h) value and required processing time will increase.

- As initial fill temperature of jars decreases, required processing time will increase.

Methods